Grating Details and Requirements

Gratings are open-grid flooring systems made from metal or fiberglass used in industrial, commercial, and infrastructure applications. They provide load-bearing capacity, drainage, ventilation, and slip resistance, making them essential for walkways, platforms, stair treads, drainage covers, and mezzanine floors.

1. Purpose & Benefits of Gratings

✔️ Provides a safe walking surface with anti-slip properties.

✔️ Allows drainage and ventilation, preventing water accumulation.

✔️ Supports heavy loads, making it suitable for industrial flooring.

✔️ Lightweight but strong, reducing structural weight.

✔️ Corrosion-resistant (especially stainless steel and FRP gratings).

2. Types of Gratings

a. Based on Material

| Material | Properties | Common Applications |

|---|---|---|

| Mild Steel (MS) | Strong, economical | Industrial walkways, platforms |

| Stainless Steel (SS 304/316) | Corrosion-resistant | Marine, food industry, chemical plants |

| Aluminum | Lightweight, rustproof | Architectural use, lightweight platforms |

| FRP (Fiberglass Reinforced Plastic) | Non-conductive, corrosion-resistant | Electrical substations, offshore platforms |

b. Based on Construction Type

| Grating Type | Description | Best Used For |

|---|---|---|

| Welded Steel Grating | Cross bars welded to bearing bars | Heavy-duty industrial floors |

| Press-Locked Grating | Pressure-locked crossbars for high strength | Architectural applications |

| Expanded Metal Grating | Stretched metal sheets forming a mesh | Security fencing, machine guards |

| Fiberglass (FRP) Grating | Resin-molded for corrosion resistance | Chemical plants, marine environments |

c. Based on Surface Type

- Plain Grating – Smooth surface, used in dry areas.

- Serrated Grating – Provides extra slip resistance.

- Galvanized Grating – Rust-proof coating for outdoor use.

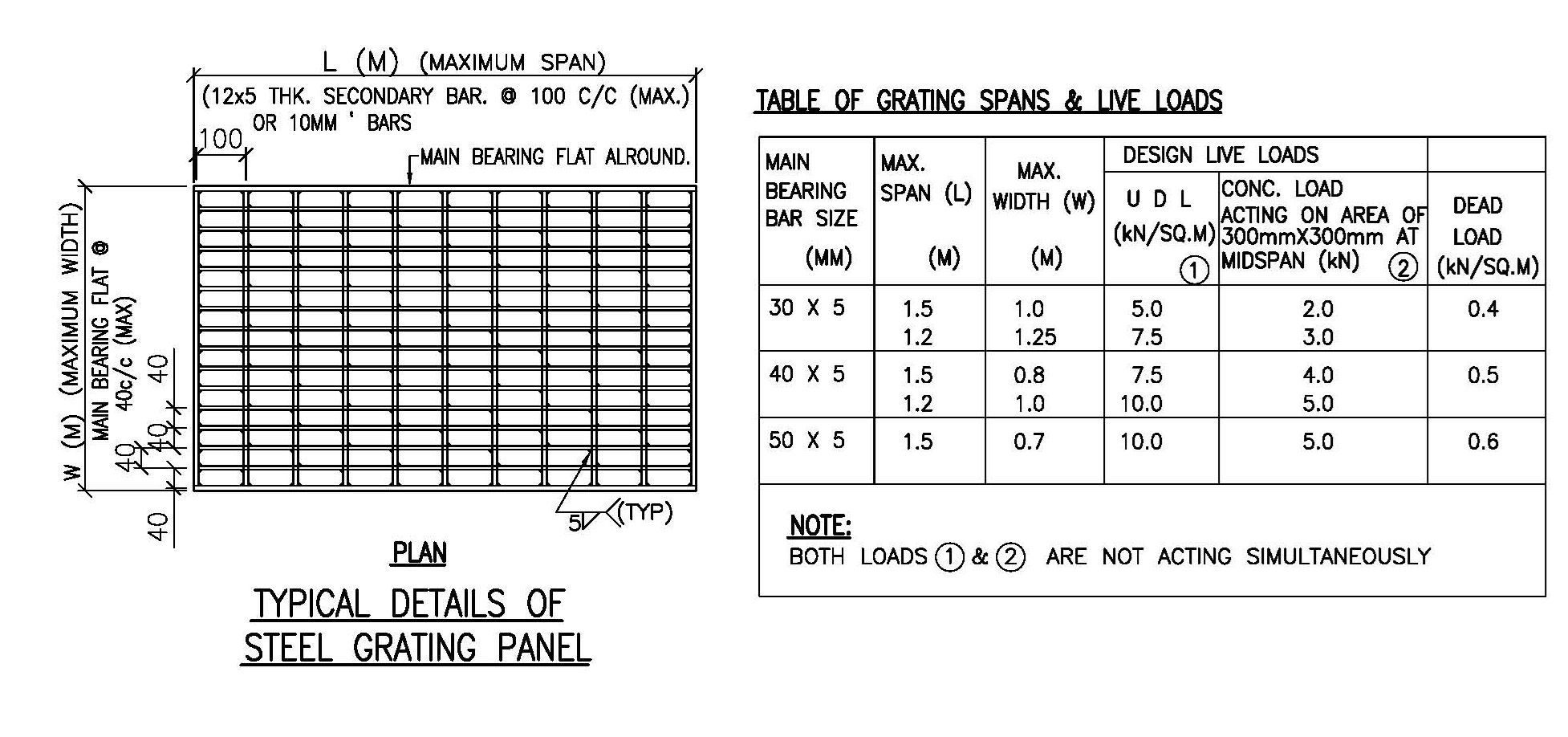

3. Standard Grating Sizes & Load Capacity

a. Common Grating Bar Spacing (Pitch)

Stair Treads: 30 mm or 40 mm bar spacing.

Steel Grating: 30 mm, 40 mm, 50 mm spacing.

FRP Grating: 38 mm, 50 mm, or custom spacing.

Grating Specification Guide

Gratings are load-bearing structures used for flooring, walkways, stair treads, platforms, drainage covers, and ventilation grilles in industrial, commercial, and infrastructure applications. Proper specification ensures safety, durability, and compliance with engineering standards.

1. Standard Specification Format for Gratings

A grating specification should include:

- Material type (Steel, Stainless Steel, Aluminum, FRP).

- Grating type (Welded, Press-Locked, Expanded Metal, FRP).

- Bar spacing and thickness (e.g., 30mm × 5mm).

- Load-bearing capacity (e.g., 5 kN/m²).

- Surface treatment (Galvanized, Powder-Coated, Painted).

- Fixing method (Welded, Bolted, Clamped).

2. Grating Materials & Their Properties

| Material | Properties | Best Used For |

|---|---|---|

| Mild Steel (MS) | High strength, cost-effective | Industrial walkways, platforms |

| Stainless Steel (SS 304/316) | Corrosion-resistant, durable | Marine, food, chemical industries |

| Aluminum | Lightweight, rustproof | Architectural & non-corrosive applications |

| Fiberglass (FRP) | Non-conductive, fire-resistant | Electrical substations, chemical plants |

3. Types of Gratings & Load Ratings

a. Types of Gratings

| Grating Type | Description | Best Used For |

|---|---|---|

| Welded Steel Grating | Cross bars welded to bearing bars | Heavy-duty industrial floors |

| Press-Locked Grating | Pressure-locked bars for high strength | Commercial and architectural use |

| Expanded Metal Grating | Stretched metal sheets forming a mesh | Security fencing, machine guards |

| Fiberglass (FRP) Grating | Resin-molded, corrosion-resistant | Chemical plants, offshore platforms |

b. Load Ratings for Gratings

| Grating Type | Uniform Load Capacity (kN/m²) | Concentrated Load Capacity (kN) |

|---|---|---|

| Light Duty Steel Grating | 5-10 kN/m² | 2.5-5 kN |

| Heavy Duty Steel Grating | 15-50 kN/m² | 10-25 kN |

| FRP Grating | 2-8 kN/m² | 1-4 kN |

4. Standard Grating Bar Spacing & Thickness

| Bar Spacing (mm) | Bearing Bar Thickness (mm) | Load Class |

|---|---|---|

| 25 mm | 3-5 mm | Light Duty |

| 30 mm | 5-8 mm | Medium Duty |

| 40 mm | 6-10 mm | Heavy Duty |

| 50 mm | 8-12 mm | Extra Heavy Duty |

Note: Spacing depends on load requirements and safety regulations.

5. Grating Surface Finishes

| Finish Type | Purpose |

|---|---|

| Hot-Dip Galvanized | Corrosion protection for outdoor use |

| Powder-Coated | Aesthetic and rust-resistant |

| Mill Finish | Untreated, used for indoor applications |

| Painted Gratings | Color-coded for safety zones |

6. Fixing Methods for Gratings

| Fixing Type | Description | Application |

|---|---|---|

| Welded Fixing | Gratings welded to steel supports | Permanent installations |

| Bolted Fixing | Bolted clips secure gratings in place | Removable flooring |

| Clamp Fixing | Quick-release clamps for modular use | Temporary access platforms |

7. International Standards for Gratings

| Standard | Region | Specification |

|---|---|---|

| IS 2062 / IS 875 | India | Structural steel grating strength |

| ASTM A1011 / A123 | USA | Load capacity, galvanized coatings |

| BS 4592 | UK | Industrial flooring standards |

| EN 14122-2 | EU | Machine access and walkway gratings |

| OSHA 1910.29 | USA | Fall protection and safety gratings |

| AS 1657 | Australia | Safe grating design for platforms |

8. Sample Grating Specification for a Project

“Supply and installation of mild steel welded grating, 30mm × 5mm bearing bars, with a 40mm cross-bar pitch, hot-dip galvanized finish, load capacity of 5 kN/m², installed with bolted clip fixing, compliant with IS 2062 and ASTM A123 standards.”

9. Conclusion

Proper grating specification ensures safety, durability, and compliance in various applications. By selecting the right material, spacing, thickness, and fixing method, gratings can provide efficient, long-lasting solutions for industrial and commercial flooring needs.

- Electrical Layout For Residential Building

- Rain Water Gutter and Down Take Systems

- Stormwater Drainage Calculation

- Structural Engineering Design Criteria – American Codes and Standards

- Insert Plate Details & Drawing – Embedded in Concrete Structures

- Anchor Bolt Details and Drawing – Embedded in Concrete

- Staircase Layout and Details

- Guard House Layout and Details

- Pump Shed Structural Steel Drawing

- Column Buckling

- Moody Chart | Moment Reactions for Rectangular Plates |

- Standard Road Details

- DG Building Architectural Plan & Finishing Schedule

- Technical Details for Wash Basin Section and Elevation

- Tender Technical Specification for Plumbing and Sanitary works

- Fencing Gate Details and Requirements

- Fencing Layout and Details For Transformer Area

- Fencing with Angle Post and Pipe Post Details & Arrangements

- Civil Engineering Formula Book | Pocket Guide pdf Free download |

- Transformer Foundation with Soak Pit Layout and Details

- Grating Standard Details and Specifications

- Chequered Plate Standard Details

- Handrail Details for Steel Structural Floors

- Cable Pull Pit Requirements and Details

- Laboratory Building Plan and Architecture Details

- Structural Bolt Details Types Grades and Applications

- Finishing Schedule Drawing for Doors, Windows, and Rolling Shutters

- Workshop Building Architectural Layout

- Calculation of Foundation Bearing Capacity as per IS 6403 – 1981

- Terzaghi’s Bearing Capacity Calculation For Foundations

- DESIGN AND CONSTRUCTION METHOD OF MULTISTORY CONCRETE BUILDINGS

- Civil Structural Engineering Interview Questions pdf Free Download

- Civil Structural Engineering Interview Questions

- SHEAR FORCE AND BENDING MOMENT DIAGRAMS WITH FORMULA

- Weathering Course in RCC Roof

- Rolling Shutter Fixing Detail with RCC Beam

- Duct Bank Details and Pipe Sleeves Details

- Handrail Details | Construction Methods and Types of Handrail |

- Details of Ramp

- Design Calculation of Steel Shelter – AISC 360

- Cage Ladder Specification and Detail Drawing

- Concrete Beam Design as per Canadian Code (CSA A23.3-19)

- Fencing Detail Drawing

- RCC Fencing Post Details

- Gypsum Board False Ceiling Installation

- Design of Anchor Reinforcement in Concrete Pedestals

- Wind Load Calculation as per IS 875 Part 3 2015

- DESIGN BASIS FOR CIVIL AND STRUCTURAL

- General Specification for Civil and Structural Works

- Green Building

- Fireproofing Details

- Response Spectrum Analysis in STAAD pro

- SHELTER WITH 25T CRANE DRAWING | PEB SHED |

- MONORAIL DETAILS

- Lifting Padeye Design

- Corbel Design and Details

- BEHAVIOUR OF STEEL CHIMNEY UNDER DYNAMIC LOADINGS

- DESIGN OF WIND PRESSURE AS PER EN 1991-1-4

- Grade Slab Details

- Resort Cottage Plan

- CONCRETE BATCHING PLANT ARRANGEMENT

- LOAD COMBINATIONS NBCC 2023

- STEEL SHED DRAWING

- Plumbing Drawing

- Pre Engineered Building Design Specification IS Code

- BATHROOM FIXTURES AND FITTINGS – European Closet, Urinal & Wash Basin

- Design of Pipe Support Foundation Calculation

- Design of Concrete Anchor Blocks

- PEB Shed Drawing