Designing a reinforced concrete (RCC) trench involves several steps to ensure it can handle the intended loads and environmental conditions. Here’s a detailed guide on designing an RCC trench, including structural design considerations, reinforcement details, and construction steps.

Key Design Considerations

- Purpose and Use

- Dimensions

- Load Requirements

- Material Specifications

- Reinforcement Details

- Drainage Provisions

- Construction Steps

1. Purpose and Use

Define the primary purpose of the trench, which could be for housing utilities (electrical cables, pipes), drainage, or other infrastructure needs.

2. Dimensions

- Width: Based on the size and number of utilities to be accommodated.

- Depth: Dependent on the type of utility and local codes (typically 2 to 6 feet).

- Length: Determined by the extent of the infrastructure.

3. Load Requirements

- Surface Loads: Vehicles, equipment, or pedestrian traffic.

- Lateral Loads: Soil pressure and other lateral forces.

4. Material Specifications

- Concrete Mix: Typically, a mix with a compressive strength of 4000 psi (27.6 MPa) is used.

- Reinforcement: High-strength steel rebars (e.g., Grade 60).

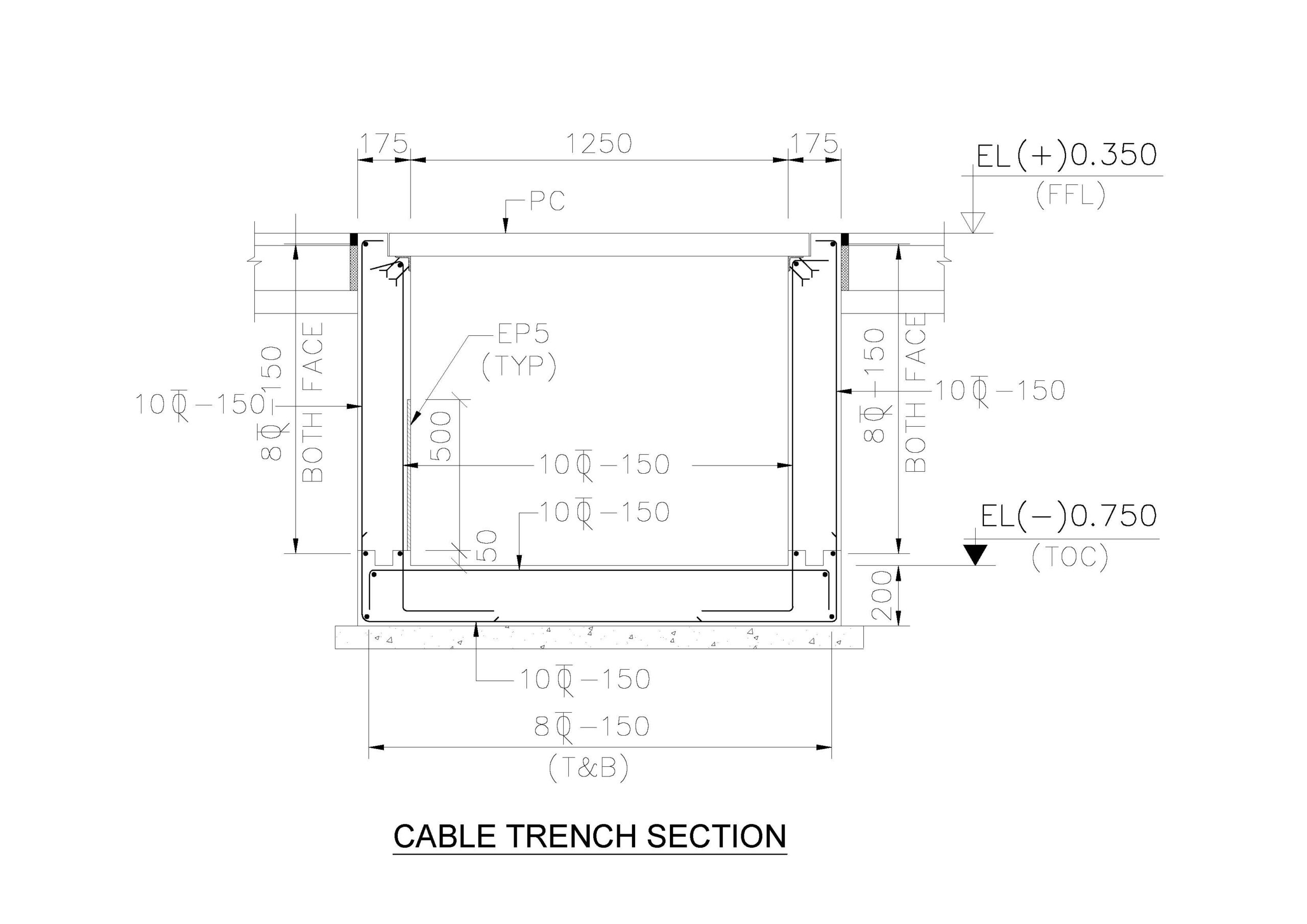

5. Reinforcement Details

- Bottom Slab: Reinforced with rebar mesh or bars.

- Side Walls: Vertical reinforcement to handle lateral loads.

- Top Slab: Reinforced to handle surface loads if used as a cover.

6. Drainage Provisions

- Drain Pipes: To prevent water accumulation.

- Slope: Design the trench with a slight slope for water runoff.

7. Construction Steps

Site Preparation

- Survey and Marking: Mark the trench path and dimensions.

- Clearing: Remove vegetation, debris, and obstacles.

Excavation

- Excavation: Excavate to the required depth and width.

- Stabilization: Use shoring if necessary to prevent soil collapse.

Sub-base Preparation

- Compaction: Compact the soil to provide a stable base.

- Gravel Base: Add a layer of compacted crushed stone for stability and drainage.

Formwork and Reinforcement

- Formwork: Install formwork for the trench bottom and walls.

- Reinforcement Placement: Place reinforcement bars according to design specifications.

Concreting

- Pouring Concrete: Pour concrete for the bottom slab, ensuring proper compaction and finishing.

- Walls: Once the bottom slab has set, pour concrete for the side walls.

- Curing: Cure the concrete properly to achieve desired strength.

Backfilling and Finishing

- Backfilling: After the concrete has cured, backfill the trench with suitable material.

- Surface Finish: Finish the top surface to match the surrounding area if required.

Example Design Calculation for an RCC Trench

Given:

- Trench Dimensions: Width = 2 feet, Depth = 4 feet, Length = 100 feet.

- Load Requirement: Light vehicle load of 2000 lbs.

- Concrete Strength: 4000 psi.

- Slab Thickness Calculation:

- Assumed Thickness: 6 inches (0.5 feet) for the bottom slab and side walls.

- Load Calculation:

- Total Load on Top Slab: 2000 lbs×1.5 (safety factor)=3000 lbs2000 \, \text{lbs} \times 1.5 \, \text{(safety factor)} = 3000 \, \text{lbs}2000lbs×1.5(safety factor)=3000lbs.

- Load per Unit Area: 3000 lbs2 ft×4 ft=375 lbs/ft2\frac{3000 \, \text{lbs}}{2 \, \text{ft} \times 4 \, \text{ft}} = 375 \, \text{lbs/ft}^22ft×4ft3000lbs=375lbs/ft2.

- Reinforcement Design:

- Bottom Slab:

- Rebar size and spacing: #4 rebar, 12 inches on center.

- Reinforcement Area: Use rebar mesh with an area of 0.2 sq in per bar.

- Side Walls:

- Vertical Rebar: #4 rebar, 12 inches on center.

- Horizontal Rebar: #4 rebar, 12 inches on center.

- Top Slab (if applicable):

- Designed similarly to the bottom slab to handle surface loads.

Final Design Specifications

- Concrete: 4000 psi mix.

- Reinforcement:

- Bottom slab: #4 rebar, 12 inches on center, both ways.

- Side walls: Vertical and horizontal #4 rebar, 12 inches on center.

- Top slab: #4 rebar, 12 inches on center, both ways (if used as cover).

- Drainage: Perforated drain pipes along the bottom with a gravel base.

- Surface Finish: Broom finish for non-slip surface on top slab if used as a cover.

Categories

- 3D HOUSE DESIGN (19)

- Civil and Structural Design Calculations (41)

- Commercial Plans (9)

- East Facing House Plans (14)

- Engineering Concepts – Civil & Structural (155)

- Excel Spreadsheets (18)

- Free Downloads (17)

- House Plans (51)

- Industrial standards (69)

- North Facing House Plans (15)

- South Facing House Plans (12)

- West Facing House Plans (7)

Designing and constructing a trench involves several considerations to ensure it meets the functional, structural, and safety requirements. Here’s a comprehensive guide to trench details, including design considerations, construction steps, and typical use cases.

Key Components of Trench Design

- Purpose and Use

- Dimensions

- Load Requirements

- Material Selection

- Drainage

- Safety Features

- Construction Process

- Purpose and Use

Define the primary purpose of the trench, which could be for utility lines, drainage, electrical cables, or other infrastructure needs.

- Dimensions

- Width: Typically determined by the type and number of utilities or pipes it needs to accommodate.

- Depth: Dependent on the type of utility and local codes (usually between 2 to 6 feet).

- Length: Based on the extent of the infrastructure being installed.

- Load Requirements

- Surface Loads: Consider the loads that will be applied on the surface, such as vehicle traffic or equipment.

- Lateral Loads: From the soil and other surrounding structures.

- Material Selection

- Concrete: For structural trenches requiring high durability.

- PVC or HDPE: For flexible, corrosion-resistant piping.

- Metal: For specific utility needs, such as gas or high-pressure water.

- Drainage

Ensure the trench design includes proper drainage to prevent water accumulation:

- Drain Pipes: Perforated pipes wrapped in geotextile fabric to filter soil.

- Gravel Base: Helps in drainage and provides stability.

- Slope: A slight slope towards drainage points or sumps.

- Safety Features

- Trench Shoring: For deep trenches to prevent collapse.

- Barrier and Signs: Around the trench during construction.

- Ladders or Ramps: For safe access in and out of the trench.

- Construction Process

Site Preparation

- Surveying: Mark the trench path and dimensions.

- Clearing: Remove vegetation, debris, and obstacles.

Excavation

- Excavation Depth and Width: Use appropriate equipment to achieve the required depth and width.

- Stabilization: Stabilize trench walls using shoring if necessary.

Sub-base Preparation

- Compaction: Compact the soil to provide a stable base.

- Granular Base: Add a layer of crushed stone or gravel for stability and drainage.

Placement of Utilities

- Positioning: Place pipes, cables, or other utilities as per the design.

- Bedding Material: Use sand or fine gravel to bed the utilities, ensuring they are well-supported and protected.

Backfilling

- Layering: Backfill in layers, compacting each layer to avoid settlement.

- Final Layer: Use topsoil or gravel to match the surrounding surface.

Example Trench Design Details

Trench for Electrical Cables

Dimensions

- Width: 2 feet

- Depth: 4 feet

- Length: 100 feet

Load Requirements

- Surface Load: Light vehicle traffic (up to 3,000 lbs)

- Lateral Load: Soil pressure based on trench depth

Materials

- Concrete Cover Slab: 6-inch thick precast concrete slabs

- PVC Conduits: For electrical cables

Drainage

- Perforated Drain Pipe: Along the bottom, wrapped in geotextile fabric

- Gravel Base: 6 inches of crushed stone

Safety Features

- Shoring: Trench boxes for stabilization

- Barriers and Signs: Around the construction site

- Access Ladders: Every 25 feet

Construction Process

- Site Preparation

- Survey and mark the trench layout.

- Clear the site of any obstacles.

- Excavation

- Excavate to a depth of 4 feet and a width of 2 feet.

- Stabilize trench walls using trench boxes.

- Sub-base Preparation

- Compact the soil at the bottom of the trench.

- Add and compact a 6-inch layer of crushed stone for drainage.

- Placement of Utilities

- Lay the perforated drain pipe along the bottom, ensuring it is wrapped in geotextile fabric.

- Position PVC conduits for electrical cables, ensuring they are well-supported and spaced.

- Backfilling

- Backfill around the conduits with sand or fine gravel, compacting in layers.

- Continue backfilling with soil, compacting each layer.

- Finish with a layer of topsoil or gravel to match the surrounding area.

Conclusion

Designing a trench requires careful consideration of the intended use, load requirements, material selection, and safety features. Proper planning and execution ensure the trench meets its functional needs while providing durability and safety. Use the example as a template and adjust dimensions, materials, and processes according to specific project requirements and local codes.

Recent Posts

- Electrical Layout For Residential Building

- HOUSE PLAN 29 X 56 | SOUTH FACING |

- Rain Water Gutter and Down Take Systems

- Stormwater Drainage Calculation

- Structural Engineering Design Criteria – American Codes and Standards

- Anchor Bolts Length as per ACI 318-14

- Insert Plate Details & Drawing – Embedded in Concrete Structures

- JOURNAL PAPER GUIDELINES FOR ACSE

- Anchor Bolt Details and Drawing – Embedded in Concrete

- Staircase Layout and Details

- Guard House Layout and Details

- Pump Shed Structural Steel Drawing

- ASCE 7-16 Wind Load on Buildings and Structures

- Column Buckling

- Moody Chart | Moment Reactions for Rectangular Plates |

- Test Pile Drawing Calculation & Guidelines

- Commercial Shop Plan

- Shop Floor Plan

- HOUSE PLAN WITH SHOP 40 x 60 | SOUTH FACING |

- Wind Load Calculation as per Australian Code (AS/NZS 1170.2:2021)

- HOUSE PLAN 30 X 45 | EAST FACING | INTERIOR HOUSE DESIGN |

- HOUSE PLAN 60 x 40 | EAST FACING | APARTMENT TYPE |

- Standard Road Details

- DG Building Architectural Plan & Finishing Schedule

- AMAZING TV UNIT IDEAS 90+ MODELS

- HOUSE PLAN 60 x 50 | EAST FACING |

- Technical Details for Wash Basin Section and Elevation

- Tender Technical Specification for Plumbing and Sanitary works

- HOUSE PLAN 25 x 50 | SOUTH FACING |

- HOUSE PLAN 60 x 45 | SOUTH FACING |

- Fencing Gate Details and Requirements

- Fencing Layout and Details For Transformer Area

- Fencing with Angle Post and Pipe Post Details & Arrangements

- Civil Engineering Formula Book | Pocket Guide pdf Free download |

- HOUSE PLAN 35 x 60 | WEST FACING |

- Transformer Foundation with Soak Pit Layout and Details

- Grating Standard Details and Specifications

- Chequered Plate Standard Details

- Handrail Details for Steel Structural Floors

- Cable Pull Pit Requirements and Details

- Laboratory Building Plan and Architecture Details

- Structural Bolt Details Types Grades and Applications

- HOUSE PLAN 40 x 60 | NORTH FACING |

- Finishing Schedule Drawing for Doors, Windows, and Rolling Shutters

- Workshop Building Architectural Layout

- Calculation of Foundation Bearing Capacity as per IS 6403 – 1981

- Terzaghi’s Bearing Capacity Calculation For Foundations

- DESIGN AND CONSTRUCTION METHOD OF MULTISTORY CONCRETE BUILDINGS

- HOUSE PLAN 60 x 60 | SOUTH FACING |

- Civil Structural Engineering Interview Questions pdf Free Download

- Civil Structural Engineering Interview Questions

- HOUSE PLAN 60 x 30 | EAST FACING |

- HOUSE PLAN 28 x 31 | WEST FACING |

- SHEAR FORCE AND BENDING MOMENT DIAGRAMS WITH FORMULA

- HOUSE PLAN 43 x 66 | SOUTH FACING |

- Canadian Code Seismic Calculation Example

- Weathering Course in RCC Roof

- Rolling Shutter Fixing Detail with RCC Beam

- HOUSE PLAN 35 x 50 | SOUTH FACING |

- APARTMENT PLAN 53 x 62 | EAST & WEST Facing |

- Duct Bank Details and Pipe Sleeves Details

- Handrail Details | Construction Methods and Types of Handrail |

- Details of Ramp

- Design Calculation of Steel Shelter – AISC 360

- Cage Ladder Specification and Detail Drawing

- Staircase Ideas 40+

- Vertical Vessel Foundation Design

- Effective Length for RCC Columns

- DESIGN OF SLABS AS PER IS456

- Design of Staircase Waist Slab

- Monorail Beam Design

- HOUSE PLAN 35 x 50 | SOUTH FACING |

- Concrete Beam Design as per Canadian Code (CSA A23.3-19)

- Wind Load Calculation as per Canadian Code | NBCC 2020 |

- Fencing Detail Drawing

- HOUSE PLAN 40 x 60 | NORTH FACING |

- HOUSE PLAN 60 x 30 | SOUTH FACING |

- RCC Fencing Post Details

- HOUSE PLAN 30 x 40 | NORTH FACING |

- HOUSE PLAN 45 x 45 | WEST FACING |

- HOUSE PLAN 40 x 40 | WEST FACING |

- HOUSE PLAN 30 x 50 | SOUTH FACING |

- Modern House Front Elevation Design

- Transformer Foundation Design

- Gypsum Board False Ceiling Installation

- Box Culvert Design

- Design of Anchor Reinforcement in Concrete Pedestals

- Wind Load Calculation for Pipe Rack

- Apartment House Plan | West Facing 60 x 60 |

- kitchen marble design 30+

- Wind Load Calculation as per IS 875 Part 3 2015

- DESIGN BASIS FOR CIVIL AND STRUCTURAL

- General Specification for Civil and Structural Works

- Green Building

- Fireproofing Details

- Response Spectrum Analysis in STAAD pro

- SHELTER WITH 25T CRANE DRAWING | PEB SHED |

- HOUSE PLAN 20 x 60 | WEST FACING |

- MONORAIL DETAILS

- WEST FACING HOUSE PLAN 50 x 40 | DUPLEX TYPE |

- Side Face Reinforcement as per ACI & IS code

- HOUSE PLANS

- HOUSE PLAN 35 x 50 | EAST FACING |

- HOUSE PLAN 25 x 60 | NORTH FACING |

- HOUSE PLAN 35 x 50 | NORTH FACING |

- Design of Cold-Formed Steel Structures as Per IS 801

- HOUSE PLAN 30 x 40 | EAST FACING |

- HOUSE PLAN 30 x 40| NORTH FACING |

- HOUSE PLAN 20 x 40 | NORTH FACING |

- Lifting Padeye Design

- Corbel Design and Details

- DYNAMIC ANALYSIS USING RESPONSE SPECTRUM ANALYSIS

- Building Load Calculation

- Deep Excavations

- Bathroom Tiles Designs Ideas 50+

- Wooden Main Door Ideas 40+

- Gate Design Ideas 60+

- Structural Design of working pile

- Design of Gantry Girder

- Modern Kitchen Interior Idea Photos 26+

- BEHAVIOUR OF STEEL CHIMNEY UNDER DYNAMIC LOADINGS

- Church Design Drawing

- Seismic Load Calculation as per ASCE 7-16

- 33×66 North Facing Ground Floor Plan with Vastu

- DESIGN OF WIND PRESSURE AS PER EN 1991-1-4

- Best 3D House Elevation Design G+1

- House Plan with Photos | Architect Detail Drawing |

- Trench Details

- PRECAST COVER SLAB DETAILS

- Grade Slab Details

- Resort Cottage Plan

- CONCRETE BATCHING PLANT ARRANGEMENT

- LOAD COMBINATIONS NBCC 2023

- STEEL SHED DRAWING

- Plumbing Drawing

- Pre Engineered Building Design Specification IS Code

- SMALL HOUSE PLAN 28 x 40 | NORTH FACING |

- DESIGN OF PIPERACK STRUCTURE

- BATHROOM FIXTURES AND FITTINGS – European Closet, Urinal & Wash Basin

- DUPLEX HOUSE PLAN 30 x 30 | EAST FACING |

- HOUSE PLAN 29 x 44 | EAST FACING | DUPLEX HOUSE

- Design of Pipe Support Foundation Calculation

- FLAT SLAB DESIGN AND DETAILING

- DIRECT ANALYSIS METHOD AISC 360-05 AND ITS IMPLEMENTATION IN STAAD

- PILE FOUNDATION | TYPE OF PILES | TEST METHODS AND SITE EXECUTION |

- HOUSE PLAN 38 x 58 | BEST EAST FACING | HOME THEATER

- Front Elevation Design 30+

- Design of Concrete Anchor Blocks

- HOUSE PLAN WITH OFFICE AT GROUND FLOOR 27 x 88 | NORTH FACING |

- Design of Shear Key in Base Plate as per IS Code

- HOUSE PLAN 45 x 40 | BEST NORTH FACING BUILDING PLAN |

- BANQUET HALL PLAN 40 x 60 | NORTH FACING |

- MARRIAGE HALL PLAN 33 x 77 | SOUTH FACING |

- COMMERCIAL PLAN 48 x 40 | NORTH FACING |

- APARTMENT TYPE HOUSE PLAN 30 x 80 | EAST FACING | 3BHK

- APARTMENT PLAN 40×50 | EAST FACING | 3BHK |

- Concrete Mix Design Calculations

- PEB Shed Drawing

- HOUSE PLAN 40 x 46 | NORTH FACING |

- DEVELOPMENT LENGTH OF REBAR