Types of Pile Foundation

- A pile foundation is a series of columns constructed into the ground to transfer loads to a lower level of subsoil.

- Piles are long cylinders made of a strong material, such as concrete or steel.

- Piles are pushed into the ground to act as a steady support for structures built on top of them

Bored Pile –Conventional Tripod Rig

- Boring by DMC Method.

- Boring by Bailor, Chisel method.

- Diameter possible 400 –1500mm.

- Pile can be chiselledinto soft rock& Hard rock.

- Lowering the reinforcement& concreting done by the rig.

- Best method for quality.

- Time consuming.

Bored Pile – Tractor Mounted Hydraulic Rig

- Boring cannot be done in Soft rock & Hard rock.

- Diameter possible is from 150mm –1000mm.

- Cannot do reinforcement lowering & Concreting, Crane required for same.

Bored Pile –Hydraulic Rotary Rig

- Boring done by Auger drilling method – Soil Auger & Rock Auger.

- Diameter possible 500mm -2500mm.

- Boring can be done in soft & HardRock.

- Boring will be faster.

- Reinforcement & Concreting canbe done with this rig.

Driven Pile –Conventional A -Frame Rig

- Piling is done by driving full casing with a pile shoe at the bottom.

- Diameter possible 300mm – 600mm.

- Pile can be done upto hard strata only.

- Progress will be faster.

Driven pile –Pneumatic Hydraulic Driven Rig

- Piling is done by driving full casing with a pile shoe at the bottom.

- Diameter possible 300mm – 600mm.

- Pile can be done upto hard strata only.

- Progress will be faster than A Frame.

Compaction pile –Vibro-Float Method

- By wet method

- By dry method

- Top feeding

- Bottom feeding

Sheet pile

- Using driven pile method

- Vibro-hammer method

- Can be done uptohard strata only.

Categories

- 3D HOUSE DESIGN (34)

- Civil and Structural Design Calculations (76)

- Commercial Plans (9)

- East Facing House Plans (14)

- Engineering Concepts – Civil & Structural (224)

- Excel Spreadsheets (37)

- Free Downloads (49)

- House Plans (57)

- Industrial standards (91)

- North Facing House Plans (15)

- South Facing House Plans (15)

- West Facing House Plans (9)

Product categories

- Civil & Structural Design Calculations (52)

- Commercial Plans (3)

- Excel Spread sheets (47)

- House Plans (13)

- Industrial drawing template (9)

- Uncategorized (0)

Initial load Test

- Test is done on a non-working pile to ascertain the design load.

- Load test is done 2.5 times the design load

- Increment is given at the rate of 20% of design load

- The next increment is given when the rate of displacement is 0.2mm per hour or else after 2 hours

- Increment is continued till 2.5 times is achieved or ultimate failure

- Displacement of pile is measured using calibrated dial gauges

- The result will be based on the lowest values of the following:

- 2/3rdof the load at which the settlement is12 mm for pile diaupto600 mm or

- 2% for pile diabetween 600 to 900 mm and 18 mm for pile diaabove 900

- 50% of the load at which the pile settlement is 10% of the diaof the pile

Routine Load test

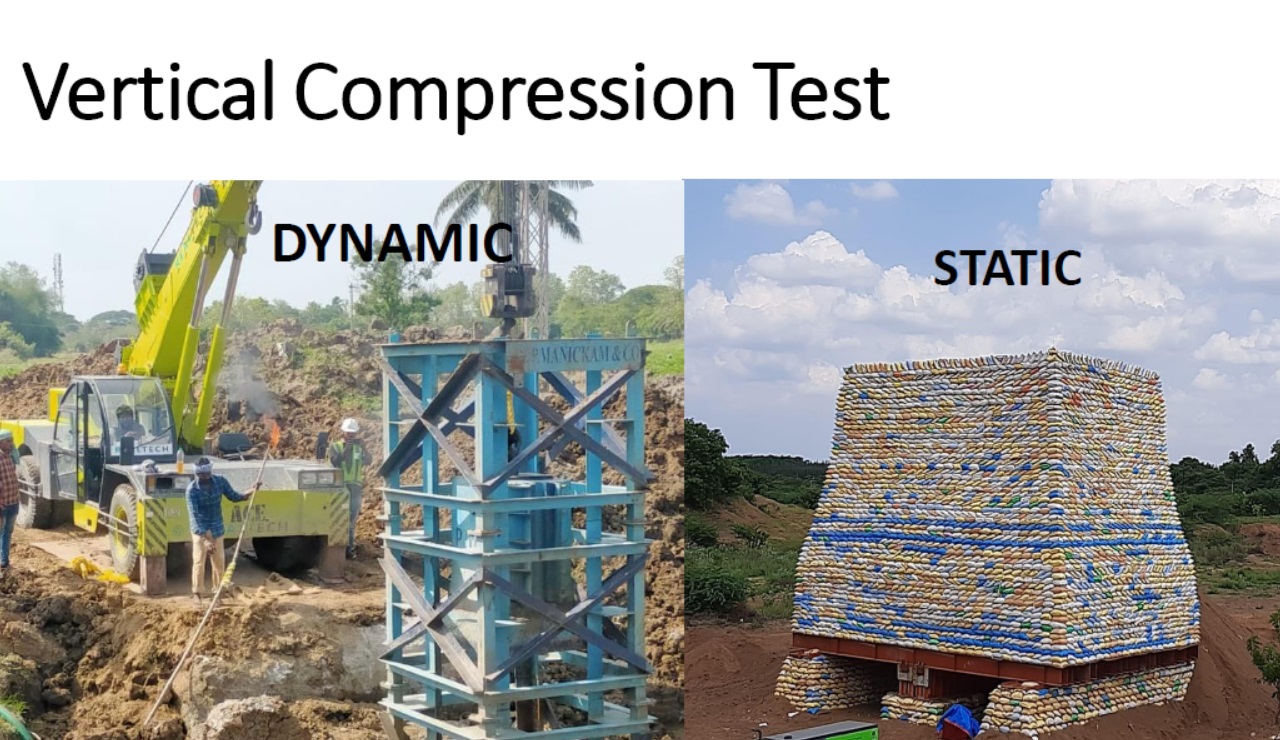

- Vertical compression Test

- Lateral test

- Pull-out test

Vertical compression test static

Lateral test

pull out test

pile integrity test

OUR BLOG POST

- Catch Basin Types and Details

- Eurocode Base Plate Calculator – EN 1993-1-8

- Base Plate Design Calculation AS 4100

- Base Plate Design Calculator CSA A23.3

- Base Plate Design Calculator ACI 318

- Base Plate Design as per IS 800 2007

- East Facing 38×56 House Plan – Ground & First Floor Design with 3BHK + Home Theatre

- Foundation Detail Drawings for Buildings With CAD Files

- Bar Bending Schedule | BBS Calculator For Beam Column and Slab

- Room Paint Calculator | Paint, Primer & Putty Quantity & Cost Estimator

- Load Conversion & Stress Calculator | kN to kg, ton, N, MPa Online

- Water Tank Capacity Calculator – Feet & Meter Conversion (Litres & Gallons)

- Brick Wall Construction Calculator | Calculate Bricks & Cost Instantly |

- Unit Converter – Feet, Inches, cm, mm, Yard to Meter and Vice Versa

- Lifting Analysis of Skid Using Spreader Beam 4-Point

- Base Plate Design as per IS Code | IS 800:2007 Steel Column Base |

- Laser Cut Railing Price in India 2025 | MS & SS CNC Balcony Designs

- MS Balcony Railing Price in India 2026 | Mild Steel Railing Works |

- Stainless Steel with Glass Handrail Price 2026

- Modern Duplex House West Facing 36 x 48

- Pooja Room Door Design

- Modern House 3D Design – Visualizing Your Dream Home

- Balcony Railing Designs for Modern Homes

- Civil Engineering Interview Questions and Important Practical Foundation

- Wind Load Calculation IS 875 Part 3 2015

- Front Elevation Design for Modern Homes

- Road Turning Radius as per IS/IRC Codes and International Standards AASHTO BS/DMRB

- Foundation Design ACI 318 pdf & Excel Download

- Steel Staircase Design

- Front Elevation 20×60 House

- Steel Shed with Mezzanine Floor

- Structural Masonry Designers Manual

- Water Supply Piping Plan and Plumbing Schematic Diagram

- Sump Pit Drawing

- Design of Steel Silo

- Design of Beam to Beam End Plate Connection

- DESIGN OF FLAT SLAB pdf Free Download

- Design of Thrust Block

- Cage Ladder Detail Standard Drawing pdf Free Download

- DESIGN OF BARREL FOR BOX CULVERT pdf Free Download

- Design of Retaining Wall Calculation pdf Free Download

- Analysis and Design of Drain Sump Pit

- Design of High Rise Buildings as per Eurocode

- Design of Steel Shelter as per IS 800

- Octagonal Pedestal Design

- Ring Wall Foundation Design

- Decking Sheet with Concrete – Design Details & Specifications

- Hydrodynamic Load on Tanks | Convective and Impulsive |

- PILE STIFFNESS CALCULATION

- HOUSE PLAN 30 X 60 | SOUTH FACING |

- Concrete Beam Design ACI 318

- Floor Slab Design One Way as per ACI 318

- Floor Slab Design Two way as per ACI 318

- Ceiling Lights and Fan Layout Details

- Floor Tile Design Ideas

- Modern Boundary walls

- Lintel Slab Layout Details

- PILE CAP Detail Drawing

- Eurocode Load Combinations EN 1990 2002

- Expansion Joint Detail and Specification

- Storm Water Drain Detail Drawing

- Thrust Blocks and Restraints Details

- HOUSE PLAN 40 X 50 | SOUTH FACING |

- Octagonal Foundation Reinforcement Details

- Loads and Load Combinations as per AS/NZS 1170.0 2002

- Design of Pump Foundation Dynamic and Static Analysis

- HOUSE PLAN 60 X 40 | WEST FACING |

- Latest Staircase Handrail Design Ideas 40+

- HOUSE PLAN 50 X 50 | SOUTH FACING |

- Electrical Layout For Residential Building

- HOUSE PLAN 29 X 56 | SOUTH FACING |

- Rain Water Gutter and Down Take Systems

- Stormwater Drainage Calculation

- Structural Engineering Design Criteria – American Codes and Standards

- Anchor Bolts Length as per ACI 318-14

- Insert Plate Details & Drawing – Embedded in Concrete Structures

- JOURNAL PAPER GUIDELINES FOR ACSE

- Anchor Bolt Details and Drawing – Embedded in Concrete

- Staircase Layout and Details

- Guard House Layout and Details

- Pump Shed Structural Steel Drawing

- Wind Load Calculations ASCE 7-16 Pdf Free Download

- Column Buckling

- Moody Chart | Moment Reactions for Rectangular Plates |

- Test Pile Drawing Calculation & Guidelines

- Commercial Shop Plan

- Shop Floor Plan

- HOUSE PLAN WITH SHOP 40 x 60 | SOUTH FACING |

- Wind Load Calculation as per Australian Code (AS/NZS 1170.2:2021)

- HOUSE PLAN 30 X 45 | EAST FACING | INTERIOR HOUSE DESIGN |

- HOUSE PLAN 60 x 40 | EAST FACING | APARTMENT TYPE |

- Standard Road Details

- DG Building Architectural Plan & Finishing Schedule

- AMAZING TV UNIT IDEAS 90+ MODELS

- HOUSE PLAN 60 x 50 | EAST FACING |

- Technical Details for Wash Basin Section and Elevation

- Tender Technical Specification for Plumbing and Sanitary works

- HOUSE PLAN 25 x 50 | SOUTH FACING |

- HOUSE PLAN 60 x 45 | SOUTH FACING |

- Fencing Gate Details and Requirements

- Fencing Layout and Details For Transformer Area

- Fencing with Angle Post and Pipe Post Details & Arrangements

- Civil Engineering Formula Book | Pocket Guide pdf Free download |

- HOUSE PLAN 35 x 60 | WEST FACING |

- Transformer Foundation with Soak Pit Layout and Details

- Grating Standard Details and Specifications

- Chequered Plate Standard Details

- Handrail Details for Steel Structural Floors

- Cable Pull Pit Requirements and Details

- Laboratory Building Plan and Architecture Details

- Structural Bolt Details Types Grades and Applications

- HOUSE PLAN 40 x 60 | NORTH FACING |

- Finishing Schedule Drawing for Doors, Windows, and Rolling Shutters

- Workshop Building Architectural Layout

- Calculation of Foundation Bearing Capacity as per IS 6403 – 1981

- Terzaghi’s Bearing Capacity Calculation For Foundations

- DESIGN AND CONSTRUCTION METHOD OF MULTISTORY CONCRETE BUILDINGS

- HOUSE PLAN 60 x 60 | SOUTH FACING |

- Civil Structural Engineering Interview Questions pdf Free Download

- Civil Structural Engineering Interview Questions

- HOUSE PLAN 60 x 30 | EAST FACING |

- HOUSE PLAN 28 x 31 | WEST FACING |

- SHEAR FORCE AND BENDING MOMENT DIAGRAMS WITH FORMULA

- HOUSE PLAN 43 x 66 | SOUTH FACING |

- Canadian Code Seismic Calculation Example

- Weathering Course in RCC Roof

- Rolling Shutter Fixing Detail with RCC Beam

- HOUSE PLAN 35 x 50 | SOUTH FACING |

- APARTMENT PLAN 53 x 62 | EAST & WEST Facing |

- Duct Bank Details and Pipe Sleeves Details

- Handrail Details | Construction Methods and Types of Handrail |

- Details of Ramp

- Design Calculation of Steel Shelter – AISC 360

- Cage Ladder Specification and Detail Drawing

- Staircase Ideas 40+

- Vertical Vessel Foundation Design

- Effective Length for RCC Columns

- DESIGN OF SLABS AS PER IS456

- Design of Staircase Waist Slab

- Monorail Beam Design

- HOUSE PLAN 35 x 50 | SOUTH FACING |

- Concrete Beam Design as per Canadian Code (CSA A23.3-19)

- Wind Load Calculation as per Canadian Code | NBCC 2020 |

- Fencing Detail Drawing

- HOUSE PLAN 40 x 60 | NORTH FACING |

- HOUSE PLAN 60 x 30 | SOUTH FACING |

- RCC Fencing Post Details

- HOUSE PLAN 30 x 40 | NORTH FACING |

- HOUSE PLAN 45 x 45 | WEST FACING |

- HOUSE PLAN 40 x 40 | WEST FACING |

- HOUSE PLAN 30 x 50 | SOUTH FACING |

- Modern House Front Elevation Design

- Transformer Foundation Design

- Gypsum Board False Ceiling Installation

- Box Culvert Design

- Design of Anchor Reinforcement in Concrete Pedestals

- Wind Load Calculation for Pipe Rack

- Apartment House Plan | West Facing 60 x 60 |

- kitchen marble design 30+

- Wind Load Calculation as Per Indian Code

- DESIGN BASIS FOR CIVIL AND STRUCTURAL

- General Specification for Civil and Structural Works

- Green Building

- Fireproofing Details

- Response Spectrum Analysis in STAAD pro

- SHELTER WITH 25T CRANE DRAWING | PEB SHED |

- HOUSE PLAN 20 x 60 | WEST FACING |

- MONORAIL DETAILS

- WEST FACING HOUSE PLAN 50 x 40 | DUPLEX TYPE |

- Side Face Reinforcement as per ACI & IS code

- HOUSE PLANS

- HOUSE PLAN 35 x 50 | EAST FACING |

- HOUSE PLAN 25 x 60 | NORTH FACING |

- HOUSE PLAN 35 x 50 | NORTH FACING |

- Design of Cold-Formed Steel Structures as Per IS 801

- HOUSE PLAN 30 x 40 | EAST FACING |

- HOUSE PLAN 30 x 40| NORTH FACING |

- HOUSE PLAN 20 x 40 | NORTH FACING |

- Lifting Padeye Design

- Corbel Design and Details

- DYNAMIC ANALYSIS USING RESPONSE SPECTRUM ANALYSIS

- Building Load Calculation

- Deep Excavations

- Bathroom Tiles Designs Ideas 50+

- Wooden Main Door Ideas 40+

- Gate Design Ideas 60+

- Structural Design of working pile

- Design of Gantry Girder

- Modern Kitchen Interior Idea Photos 26+

- BEHAVIOUR OF STEEL CHIMNEY UNDER DYNAMIC LOADINGS

- Church Design Drawing

- Seismic Load Calculation as per ASCE 7-16

- 33×66 North Facing Ground Floor Plan with Vastu

- DESIGN OF WIND PRESSURE AS PER EN 1991-1-4

- Best 3D House Elevation Design G+1

- House Plan with Photos | Architect Detail Drawing |

- Trench Details

- PRECAST COVER SLAB DETAILS

- Grade Slab Details

- Resort Cottage Plan

- CONCRETE BATCHING PLANT ARRANGEMENT

- LOAD COMBINATIONS NBCC 2023

- STEEL SHED DRAWING

- Plumbing Drawing

- Pre Engineered Building Design Specification IS Code

- SMALL HOUSE PLAN 28 x 40 | NORTH FACING |

- DESIGN OF PIPERACK STRUCTURE

- BATHROOM FIXTURES AND FITTINGS – European Closet, Urinal & Wash Basin

- DUPLEX HOUSE PLAN 30 x 30 | EAST FACING |

- HOUSE PLAN 29 x 44 | EAST FACING | DUPLEX HOUSE

- Design of Pipe Support Foundation Calculation

- FLAT SLAB DESIGN AND DETAILING

- DIRECT ANALYSIS METHOD AISC 360-05 AND ITS IMPLEMENTATION IN STAAD

- PILE FOUNDATION | TYPE OF PILES | TEST METHODS AND SITE EXECUTION |

- HOUSE PLAN 38 x 58 | BEST EAST FACING | HOME THEATER

- Front Elevation Design 30+

- Design of Concrete Anchor Blocks

- HOUSE PLAN WITH OFFICE AT GROUND FLOOR 27 x 88 | NORTH FACING |

- Design of Shear Key in Base Plate as per IS Code

- HOUSE PLAN 45 x 40 | BEST NORTH FACING BUILDING PLAN |

- BANQUET HALL PLAN 40 x 60 | NORTH FACING |

- MARRIAGE HALL PLAN 33 x 77 | SOUTH FACING |

- COMMERCIAL PLAN 48 x 40 | NORTH FACING |

- APARTMENT TYPE HOUSE PLAN 30 x 80 | EAST FACING | 3BHK

- APARTMENT PLAN 40×50 | EAST FACING | 3BHK |

- Concrete Mix Design Calculations

- PEB Shed Drawing

- HOUSE PLAN 40 x 46 | NORTH FACING |

- DEVELOPMENT LENGTH OF REBAR

Related Posts: