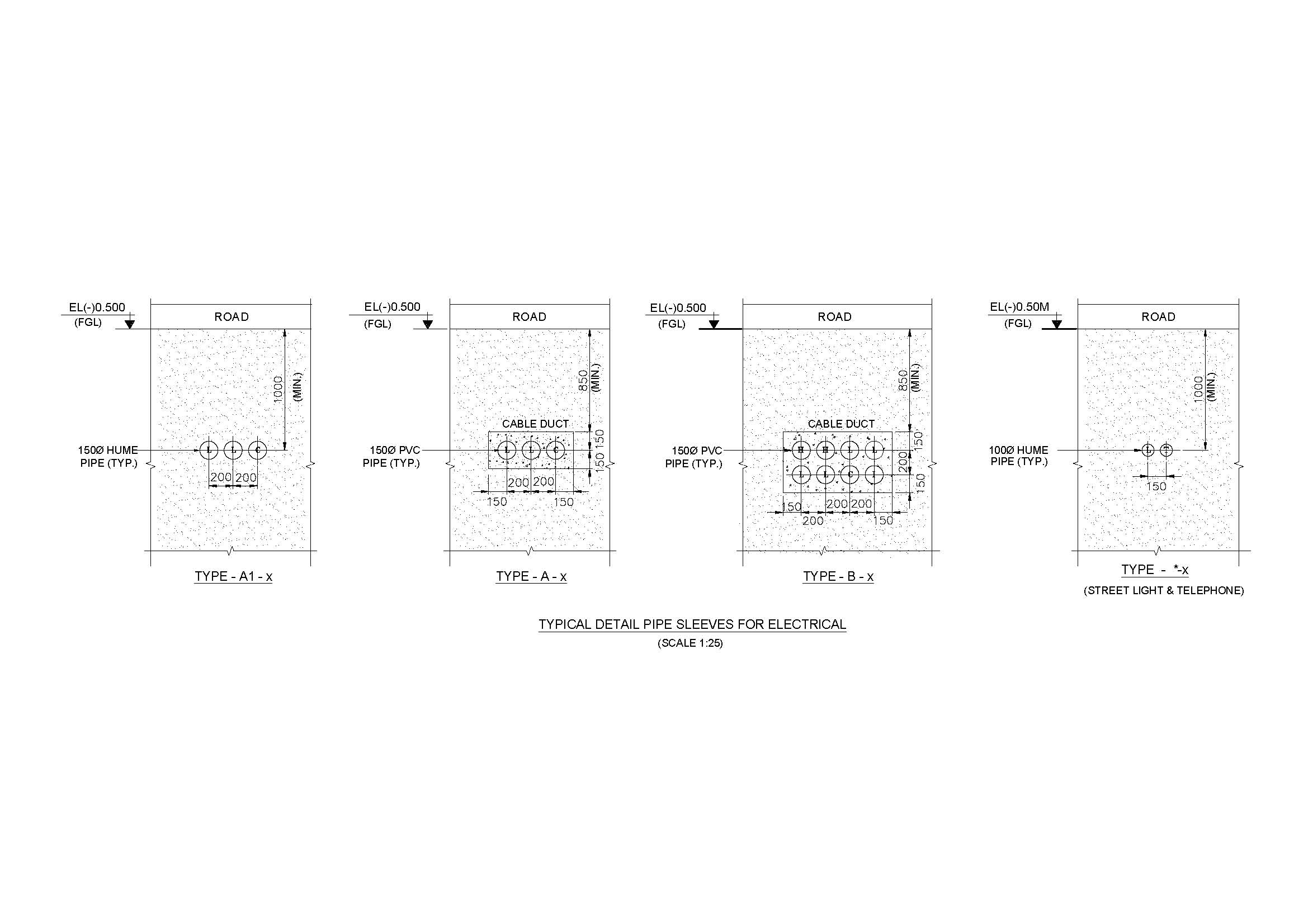

Duct Bank Details and Pipe Sleeves Details

A duct bank is an underground network of conduits (typically PVC, HDPE, or concrete) encased in concrete to provide a protected pathway for electrical cables, communication lines, or other utilities. Duct banks are widely used in industrial plants, power distribution networks, and commercial infrastructure to organize and protect cables from physical and environmental damage.

1. General Layout Drawings

- Duct Bank Plan View:

- Shows the routing of the duct bank.

- Includes:

- Conduit alignment.

- Turning points and offsets.

- Junction or pull box locations.

- Cable entry/exit points.

- Duct Bank Elevation View:

- Displays depth, conduit arrangement, and changes in elevation.

- Includes:

- Trench depth and width.

- Transition sections (e.g., rising from buried sections to above ground).

- Pull box placement.

2. Cross-Section Drawings

- Typical Duct Bank Cross-Section:

- Conduit arrangement:

- Single-layer or multi-tier configuration.

- Details of spacing between conduits:

- Horizontal: 75–100 mm.

- Vertical: 75–150 mm.

- Concrete encasement thickness:

- Minimum 75 mm on all sides.

- Reinforcement (if applicable):

- Placement of rebar or mesh.

- Direct-Buried Duct Bank Section:

- Shows conduits placed directly in the trench.

- Includes:

- Sand or gravel bedding layer (typically 150 mm).

- Warning tape placement above conduits.

- Minimum cover (e.g., 600 mm for roads, 1 m for heavy loads).

- Multi-Tier Duct Bank Section:

- Illustrates stacking of conduits in vertical layers.

- Includes:

- Spacers between layers.

- Adequate concrete cover for thermal dissipation.

3. Termination and Transition Drawings

- Duct Bank to Manhole/Pull Box Transition:

- Shows conduit entry points into manholes or pull boxes.

- Includes:

- Spacing of conduits entering the box.

- Grouting or sealing methods.

- Duct Bank to Equipment Transition:

- Illustrates how conduits connect to transformers, switchgear, or other equipment.

- Includes conduit stubs and protective covers.

4. Trench Details

- Trench Excavation and Backfill Section:

- Details trench depth, width, and side slope (if required).

- Includes:

- Bedding layer material and thickness.

- Backfill material (e.g., soil, sand, or gravel).

- Warning tape placement.

- Joint Details for Precast Duct Banks:

- Explains how precast sections are joined on-site.

- Includes:

- Sealant or grout for water-tight connections.

- Anchoring methods.

5. Reinforcement Details

- Concrete Encasement Reinforcement:

- Placement of rebar or wire mesh in the concrete surrounding the conduits.

- Includes:

- Bar sizes and spacing (e.g., 10–16 mm bars, 200 mm c/c).

- Overlapping lengths and anchoring points.

6. Fire Barrier/Separation Drawings

- Fire-Resistant Barriers:

- For duct banks passing through fire-rated walls or floors.

- Includes:

- Firestop materials (e.g., intumescent seals).

- Conduit spacing and fireproofing thickness.

7. Other Important Drawings

- Expansion Joint Details:

- For accommodating thermal expansion in long duct bank runs.

- Includes joint material and spacing.

- Drainage Details:

- For duct banks in areas prone to water accumulation.

- Includes drain pipes, sumps, or weep holes.

- Cable Pulling Section:

- Shows methods for cable installation within the conduits.

- Includes pulling points, tension loads, and lubrication access.

1. Types of Duct Banks

Duct banks are classified based on purpose, construction method, and layout:

a. Based on Purpose

- Electrical Duct Bank:

- Designed for high-voltage or low-voltage power cables.

- Includes separation between phases for electrical safety.

- Telecommunication Duct Bank:

- Houses fiber optic cables or copper communication cables.

- Includes provisions for pulling cables and splicing points.

- Combined Utility Duct Bank:

- Integrates both electrical and communication cables in separate conduits.

- Often used in urban infrastructure to minimize excavation.

b. Based on Construction Method

- Encased Duct Bank:

- Conduits are embedded in concrete for protection and mechanical strength.

- Used in high-traffic or load-bearing areas to prevent damage.

- Direct-Buried Duct Bank:

- Conduits are buried directly in the ground without concrete encasement.

- Used in areas with minimal load or where cost is a priority.

- Precast Duct Bank:

- Precast concrete sections containing conduits are manufactured off-site and installed on-site.

- Suitable for modular and fast construction.

c. Based on Layout

- Single-Tier Duct Bank:

- Conduits are arranged in a single horizontal layer.

- Ideal for shallow installations.

- Multi-Tier Duct Bank:

- Conduits are arranged in multiple layers, stacked vertically.

- Suitable for high-capacity installations with limited space.

2. Duct Bank Construction Methods

a. Conventional Cast-in-Place Construction

- Excavation:

- Dig a trench to the required depth (typically 600 mm to 1.5 m) based on the type of cables and load requirements.

- Compact the base and add a bedding layer (sand or gravel).

- Conduit Installation:

- Place conduits on spacers to maintain alignment and spacing.

- Typical spacing between conduits: 75–100 mm (to allow for heat dissipation).

- Reinforcement:

- Place reinforcement bars or mesh if required for load-bearing applications.

- Concrete Encasement:

- Pour concrete (typically M25 or M30 grade) to encase the conduits.

- Ensure proper vibration to avoid voids.

- Backfilling:

- Backfill the trench with compacted soil or suitable fill material.

b. Precast Duct Bank Construction

- Precast Duct Sections:

- Pre-fabricated concrete sections containing conduits are manufactured off-site.

- Sections include pulling points or handholes.

- Installation:

- Place precast sections in an excavated trench and align them.

- Joint Sealing:

- Seal joints between precast sections to prevent water ingress.

- Backfilling:

- Backfill with compacted soil after installation.

c. Direct Burial Method

- Conduit Burial:

- Conduits are placed directly on a sand bed and buried without concrete encasement.

- Protective Cover:

- Use warning tapes or slabs above conduits for protection and identification.

3. Key Design Considerations

a. Conduit Materials:

- PVC:

- Lightweight, cost-effective, and corrosion-resistant.

- Suitable for most utility applications.

- HDPE:

- Flexible and impact-resistant.

- Common in areas with soil movement or seismic activity.

- Galvanized Steel:

- Used for industrial or heavy-duty applications.

- Corrosion-resistant coating required for underground installations.

b. Conduit Size:

- Standard sizes: 50 mm, 100 mm, 150 mm diameter.

- Size depends on cable diameter and number of cables.

c. Separation Between Conduits:

- Maintain at least 75 mm spacing for thermal dissipation.

d. Duct Bank Size and Configuration:

- Configure duct banks based on the number of conduits.

- For multi-tier banks, add vertical spacers between layers.

4. Testing and Inspection

- Conduit Testing:

- Perform mandrel testing to check for blockages.

- Air or water pressure testing for leak-proof conduits.

- Concrete Quality Testing:

- Ensure proper curing and compressive strength of encasement.

- Post-Construction Inspection:

- Verify conduit alignment, spacing, and encasement.

5. Standards and Codes

- IS 1255 – Installation and maintenance of power cables.

- NFPA 70 (NEC) – National Electrical Code for underground duct banks.

- BS 7671 – Requirements for electrical installations.

- IEEE 525 – Guide for the design and installation of cable systems.

6. Applications of Duct Banks

- Power Plants:

- Underground duct banks for distributing high-voltage cables.

- Urban Infrastructure:

- Used for communication and power distribution in cities.

- Industrial Plants:

- Protect cables from mechanical damage in heavy-duty environments.

- Data Centers:

- For high-density cable management.

Let me know if you’d like specific design calculations or drawings for duct banks!

- 3D HOUSE DESIGN (21)

- Civil and Structural Design Calculations (43)

- Commercial Plans (9)

- East Facing House Plans (14)

- Engineering Concepts – Civil & Structural (160)

- Excel Spreadsheets (18)

- Free Downloads (20)

- House Plans (53)

- Industrial standards (70)

- North Facing House Plans (15)

- South Facing House Plans (13)

- West Facing House Plans (8)

- Loads and Load Combinations as per AS/NZS 1170.0 2002

- Design of Pump Foundation Dynamic and Static Analysis

- Electrical Layout For Residential Building

- Rain Water Gutter and Down Take Systems

- Stormwater Drainage Calculation

- Structural Engineering Design Criteria – American Codes and Standards

- Anchor Bolts Length as per ACI 318-14

- Insert Plate Details & Drawing – Embedded in Concrete Structures

- Anchor Bolt Details and Drawing – Embedded in Concrete

- Staircase Layout and Details

- Guard House Layout and Details

- Pump Shed Structural Steel Drawing

- ASCE 7-16 Wind Load on Buildings and Structures

- Column Buckling

- Moody Chart | Moment Reactions for Rectangular Plates |

- Test Pile Drawing Calculation & Guidelines

- Wind Load Calculation as per Australian Code (AS/NZS 1170.2:2021)

- Standard Road Details

- DG Building Architectural Plan & Finishing Schedule

- Technical Details for Wash Basin Section and Elevation

- Tender Technical Specification for Plumbing and Sanitary works

- Fencing Gate Details and Requirements

- Fencing Layout and Details For Transformer Area

- Fencing with Angle Post and Pipe Post Details & Arrangements

- Civil Engineering Formula Book | Pocket Guide pdf Free download |

- Transformer Foundation with Soak Pit Layout and Details

- Grating Standard Details and Specifications

- Chequered Plate Standard Details

- Handrail Details for Steel Structural Floors

- Cable Pull Pit Requirements and Details

- Laboratory Building Plan and Architecture Details

- Structural Bolt Details Types Grades and Applications

- Finishing Schedule Drawing for Doors, Windows, and Rolling Shutters

- Workshop Building Architectural Layout

- Calculation of Foundation Bearing Capacity as per IS 6403 – 1981

- Terzaghi’s Bearing Capacity Calculation For Foundations

- DESIGN AND CONSTRUCTION METHOD OF MULTISTORY CONCRETE BUILDINGS

- Civil Structural Engineering Interview Questions pdf Free Download

- Civil Structural Engineering Interview Questions

- SHEAR FORCE AND BENDING MOMENT DIAGRAMS WITH FORMULA

- Canadian Code Seismic Calculation Example

- Weathering Course in RCC Roof

- Rolling Shutter Fixing Detail with RCC Beam

- Duct Bank Details and Pipe Sleeves Details

- Handrail Details | Construction Methods and Types of Handrail |

- Details of Ramp

- Design Calculation of Steel Shelter – AISC 360

- Cage Ladder Specification and Detail Drawing

- Vertical Vessel Foundation Design

- Effective Length for RCC Columns

- DESIGN OF SLABS AS PER IS456

- Design of Staircase Waist Slab

- Monorail Beam Design

- Concrete Beam Design as per Canadian Code (CSA A23.3-19)

- Wind Load Calculation as per Canadian Code | NBCC 2020 |

- Fencing Detail Drawing

- RCC Fencing Post Details

- Transformer Foundation Design

- Gypsum Board False Ceiling Installation

- Box Culvert Design

- Design of Anchor Reinforcement in Concrete Pedestals

- Wind Load Calculation for Pipe Rack

- Wind Load Calculation as per IS 875 Part 3 2015

- DESIGN BASIS FOR CIVIL AND STRUCTURAL

- General Specification for Civil and Structural Works

- Green Building

- Fireproofing Details

- Response Spectrum Analysis in STAAD pro

- SHELTER WITH 25T CRANE DRAWING | PEB SHED |

- MONORAIL DETAILS

- Side Face Reinforcement as per ACI & IS code

- Lifting Padeye Design

- Corbel Design and Details

- DYNAMIC ANALYSIS USING RESPONSE SPECTRUM ANALYSIS

- Building Load Calculation

- Deep Excavations

- Structural Design of working pile

- Design of Gantry Girder

- BEHAVIOUR OF STEEL CHIMNEY UNDER DYNAMIC LOADINGS

- Seismic Load Calculation as per ASCE 7-16

- DESIGN OF WIND PRESSURE AS PER EN 1991-1-4

- Trench Details

- PRECAST COVER SLAB DETAILS

- Grade Slab Details

- Resort Cottage Plan

- CONCRETE BATCHING PLANT ARRANGEMENT

- LOAD COMBINATIONS NBCC 2023

- STEEL SHED DRAWING

- Plumbing Drawing

- Pre Engineered Building Design Specification IS Code

- DESIGN OF PIPERACK STRUCTURE

- BATHROOM FIXTURES AND FITTINGS – European Closet, Urinal & Wash Basin

- Design of Pipe Support Foundation Calculation

- Design of Concrete Anchor Blocks

- PEB Shed Drawing

Related Posts: