Rolling Shutter Fixing Detail with RCC Beam

Rolling shutters are often used in commercial, industrial, and residential buildings for security and ease of operation. Fixing a rolling shutter to an RCC beam requires precise detailing to ensure stability, durability, and proper functionality.

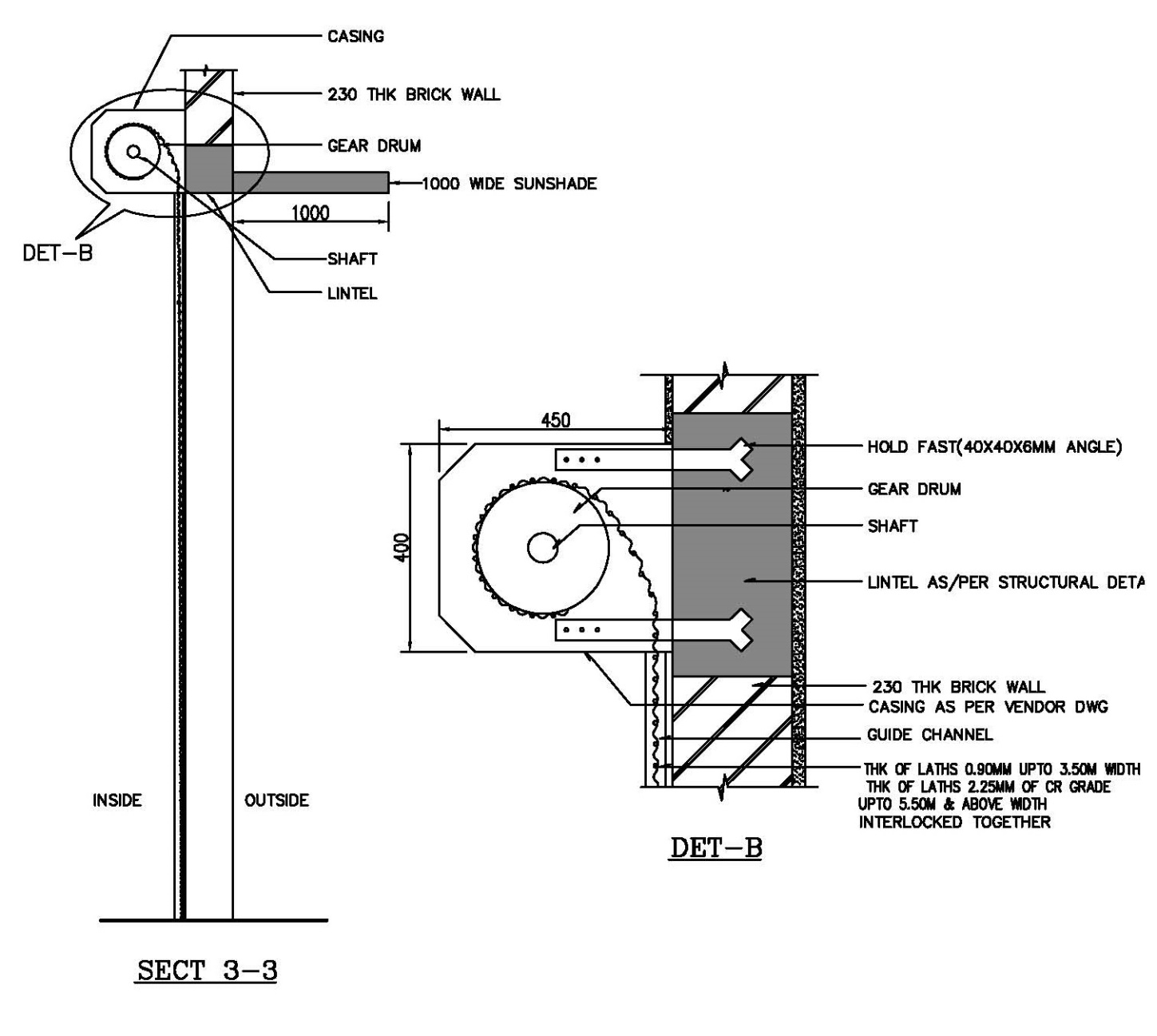

1. Components of Rolling Shutter Fixing

- RCC Beam:

- Acts as the primary structural support for the rolling shutter assembly.

- Designed to carry the weight of the shutter and any operational loads.

- Rolling Shutter Components:

- Shutter Curtain: Made of galvanized steel, aluminum, or stainless steel.

- Barrel/Drum: A circular shaft around which the shutter rolls.

- End Brackets: Steel brackets to hold the barrel.

- Side Guides: Channels installed on both sides to guide the shutter curtain.

- Bottom Rail: Reinforced edge for smooth operation.

- Fixing Accessories:

- Anchor bolts.

- Plates or clamps.

- Fasteners (nuts and bolts).

- Shutter box (optional, for aesthetics).

2. Fixing Method

a. Preparation

- RCC Beam Design:

- The beam should be designed to carry the rolling shutter’s weight and operational load.

- Typical beam dimensions: 150 mm width x 230 mm depth (or as per structural requirements).

- Embedded Inserts:

- Install anchor bolts or embedded plates during the beam casting stage to secure the shutter frame.

b. Fixing the Shutter

- Install End Brackets:

- Fix the end brackets to the RCC beam using anchor bolts or embedded plates.

- Use M12 or M16 anchor bolts for heavy-duty shutters.

- Ensure alignment for smooth rotation of the barrel.

- Attach the Barrel/Drum:

- Mount the barrel on the end brackets.

- Ensure it is level and rotates freely.

- Install Side Guides:

- Fix the vertical side guides to the wall or column adjacent to the shutter opening.

- Ensure guides are plumb and aligned with the barrel.

- Fix the Shutter Curtain:

- Attach the curtain to the barrel and check for smooth operation.

- Install the bottom rail for added stability.

- Optional Shutter Box:

- Install a shutter box or cover to protect the rolling mechanism from dust and weather.

3. Typical Rolling Shutter Fixing Details

- Beam-to-Bracket Connection:

- Use anchor bolts (expansion or chemical) to secure the end brackets to the RCC beam.

- Spacing: Typically 100–150 mm from the edges.

- Shutter Curtain-to-Barrel Connection:

- Secure the curtain to the barrel using clamps or rivets.

- Ensure balanced tension for smooth rolling.

- Guide Channel Fixing:

- Fix side guides to adjacent walls or vertical columns using fasteners.

- Provide a gap of 5–10 mm between the curtain and the guides to prevent jamming.

- Clearance:

- Maintain a clearance of 50–75 mm between the beam and the barrel to avoid friction.

4. Reinforcement and Structural Requirements

- RCC Beam Reinforcement:

- Longitudinal reinforcement: 12–16 mm dia bars.

- Stirrups: 8 mm dia @ 150 mm c/c.

- Load Transfer:

- The beam should transfer the shutter’s load safely to adjacent columns or walls.

5. Finishing

- Apply a protective coating (e.g., paint or galvanization) to prevent corrosion.

- Seal gaps around the shutter frame with weatherproofing material.

6. Standards and Codes

- IS 456:2000: For RCC beam design.

- NBC (National Building Code of India): For fixing details and safety standards.

- IS 6248: Indian standard for rolling shutters.

- Octagonal Foundation Reinforcement DetailsAn octagonal foundation is a specialized structural base often used… Read more: Octagonal Foundation Reinforcement Details

- Design of Pump Foundation Dynamic and Static AnalysisDynamic Pump Foundation Design: Vibration and Amplitude Checks Explained To… Read more: Design of Pump Foundation Dynamic and Static Analysis

- Electrical Layout For Residential BuildingCreating an electrical layout for a house involves planning the… Read more: Electrical Layout For Residential Building

- Rain Water Gutter and Down Take SystemsTypical Gutter and Downpipe Systems: An Overview Understanding Rain Water… Read more: Rain Water Gutter and Down Take Systems

- Stormwater Drainage CalculationDesigning 🌧️ Stormwater Drainage systems is essential to ensure the… Read more: Stormwater Drainage Calculation

- Structural Engineering Design Criteria – American Codes and StandardsIn the United States, structural engineering design is governed by… Read more: Structural Engineering Design Criteria – American Codes and Standards

- Insert Plate Details & Drawing – Embedded in Concrete StructuresInsert plates are embedded steel plates installed in concrete elements… Read more: Insert Plate Details & Drawing – Embedded in Concrete Structures

- Anchor Bolt Details and Drawing – Embedded in ConcreteAnchor bolts are crucial elements in structural and foundation systems,… Read more: Anchor Bolt Details and Drawing – Embedded in Concrete

- Staircase Layout and DetailsA staircase is an essential architectural element that provides vertical… Read more: Staircase Layout and Details

- Guard House Layout and DetailsA guard house, also known as a security cabin or… Read more: Guard House Layout and Details

- Pump Shed Structural Steel DrawingA pump shed is a small but critical structure designed… Read more: Pump Shed Structural Steel Drawing

- Column BucklingIntroduction Structural dynamics problems deal with structures in motion. Examples… Read more: Column Buckling

- Moody Chart | Moment Reactions for Rectangular Plates |Introduction to Moody’s Chart for Slab Design Moody’s Chart is… Read more: Moody Chart | Moment Reactions for Rectangular Plates |

- Standard Road DetailsRigid & Flexible Road Details – Drawings & Requirements Road… Read more: Standard Road Details

- DG Building Architectural Plan & Finishing ScheduleA DG (Diesel Generator) building is a dedicated structure designed… Read more: DG Building Architectural Plan & Finishing Schedule

- Technical Details for Wash Basin Section and ElevationA wash basin is an essential plumbing fixture used in… Read more: Technical Details for Wash Basin Section and Elevation

- Tender Technical Specification for Plumbing and Sanitary worksTender Technical Specification for Factory buildings – Plumbing and Sanitary… Read more: Tender Technical Specification for Plumbing and Sanitary works

- Fencing Gate Details and RequirementsA fencing gate is an essential component of any secure… Read more: Fencing Gate Details and Requirements

- Fencing Layout and Details For Transformer AreaTransformer fencing is an essential safety requirement to protect electrical… Read more: Fencing Layout and Details For Transformer Area

- Fencing with Angle Post and Pipe Post Details & ArrangementsFencing using angle posts and pipe (dia) posts is widely… Read more: Fencing with Angle Post and Pipe Post Details & Arrangements

- Civil Engineering Formula Book | Pocket Guide pdf Free download |Civil Engineering Formula Book – Essential Reference for Engineers Civil… Read more: Civil Engineering Formula Book | Pocket Guide pdf Free download |

- Transformer Foundation with Soak Pit Layout and DetailsA transformer foundation with a soak pit is designed to… Read more: Transformer Foundation with Soak Pit Layout and Details

- Grating Standard Details and SpecificationsGrating Details and Requirements Gratings are open-grid flooring systems made… Read more: Grating Standard Details and Specifications

- Chequered Plate Standard DetailsChequered Plate Standard Details A chequered plate (also known as… Read more: Chequered Plate Standard Details

- Handrail Details for Steel Structural FloorsDetails and Requirements of Handrails for Steel Structural Floors Handrails… Read more: Handrail Details for Steel Structural Floors

- Cable Pull Pit Requirements and DetailsCable Pull Pit Requirements and Details A cable pull pit… Read more: Cable Pull Pit Requirements and Details

- Laboratory Building Plan and Architecture DetailsLaboratory Building Plan Requirements for Industries Designing an industrial laboratory… Read more: Laboratory Building Plan and Architecture Details

- Structural Bolt Details Types Grades and ApplicationsStructural Bolt Details: Types, Grades, and Applications Structural bolts are… Read more: Structural Bolt Details Types Grades and Applications

- Finishing Schedule Drawing for Doors, Windows, and Rolling ShuttersHow to Prepare a Finishing Schedule Drawing for Doors, Windows,… Read more: Finishing Schedule Drawing for Doors, Windows, and Rolling Shutters

- Workshop Building Architectural LayoutHow to Prepare an Architectural Layout for a Workshop Building… Read more: Workshop Building Architectural Layout

- Calculation of Foundation Bearing Capacity as per IS 6403 – 1981The IS 6403:1981 standard provides guidelines for calculating the bearing… Read more: Calculation of Foundation Bearing Capacity as per IS 6403 – 1981

- Terzaghi’s Bearing Capacity Calculation For FoundationsHow to Calculate Bearing Capacity of a Foundation The bearing… Read more: Terzaghi’s Bearing Capacity Calculation For Foundations

- DESIGN AND CONSTRUCTION METHOD OF MULTISTORY CONCRETE BUILDINGSThe recommendations which should be taken into account in designing… Read more: DESIGN AND CONSTRUCTION METHOD OF MULTISTORY CONCRETE BUILDINGS

- Civil Structural Engineering Interview Questions pdf Free DownloadAre you preparing for a Civil or Structural Engineering job… Read more: Civil Structural Engineering Interview Questions pdf Free Download

- Civil Structural Engineering Interview QuestionsCivil & Structural Engineering Interview Questions Here’s a comprehensive list… Read more: Civil Structural Engineering Interview Questions

- SHEAR FORCE AND BENDING MOMENT DIAGRAMS WITH FORMULAIntroduction Figures 1 through 32 provides a series of shear… Read more: SHEAR FORCE AND BENDING MOMENT DIAGRAMS WITH FORMULA

- Weathering Course in RCC RoofProcedure for Weathering Course in RCC Roof A weathering course… Read more: Weathering Course in RCC Roof

- Rolling Shutter Fixing Detail with RCC BeamRolling Shutter Fixing Detail with RCC Beam Rolling shutters are… Read more: Rolling Shutter Fixing Detail with RCC Beam

- Duct Bank Details and Pipe Sleeves DetailsDuct Bank Details and Pipe Sleeves Details A duct bank… Read more: Duct Bank Details and Pipe Sleeves Details

- Handrail Details | Construction Methods and Types of Handrail |Methods of Typical Handrail Construction in RCC Structures Handrails in… Read more: Handrail Details | Construction Methods and Types of Handrail |

- Details of RampMethods and Details of Ramp Construction Ramps are inclined surfaces… Read more: Details of Ramp

- Design Calculation of Steel Shelter – AISC 360PURPOSE AND SCOPE The scope of this document is to… Read more: Design Calculation of Steel Shelter – AISC 360

- Cage Ladder Specification and Detail DrawingDetailed Specification for Steel Cage Ladders Steel cage ladders are… Read more: Cage Ladder Specification and Detail Drawing

- Concrete Beam Design as per Canadian Code (CSA A23.3-19)Concrete Beam Design as per Canadian Code (CSA A23.3-19) The… Read more: Concrete Beam Design as per Canadian Code (CSA A23.3-19)

- Fencing Detail DrawingFencing Detail Drawing Requirements To create a comprehensive fencing detail… Read more: Fencing Detail Drawing

- RCC Fencing Post DetailsRequirements for RCC Fence Posts RCC (Reinforced Cement Concrete) posts… Read more: RCC Fencing Post Details

- Gypsum Board False Ceiling InstallationGypsum board false ceiling installation layout and details Installing a… Read more: Gypsum Board False Ceiling Installation

- Design of Anchor Reinforcement in Concrete PedestalsDesign of Anchor Reinforcement in Concrete Pedestals Pedestal rebars parallel… Read more: Design of Anchor Reinforcement in Concrete Pedestals

- Wind Load Calculation as per IS 875 Part 3 2015Wind Load Calculation Wind speed -33m/sec From Ground floor to… Read more: Wind Load Calculation as per IS 875 Part 3 2015

- DESIGN BASIS FOR CIVIL AND STRUCTURALDesign Basis for Civil and Structural SPECIFIC DESIGN REQUIREMENTS [CIVIL]… Read more: DESIGN BASIS FOR CIVIL AND STRUCTURAL

- General Specification for Civil and Structural WorksCONTENTS CLAUSE NO. DESCRIPTION PAGE NO. 1.00.00 INTRODUCTION 1 2.00.00… Read more: General Specification for Civil and Structural Works

- Green BuildingA green building is a structure designed, constructed, and operated… Read more: Green Building

- Fireproofing DetailsFireproofing, also known as fire-resistive protection, is crucial for structural… Read more: Fireproofing Details

- Response Spectrum Analysis in STAAD proIn STAAD.Pro, combining loads using the SRSS (Square Root of… Read more: Response Spectrum Analysis in STAAD pro

- SHELTER WITH 25T CRANE DRAWING | PEB SHED |Designing a shelter with a 25-ton capacity crane involves structural… Read more: SHELTER WITH 25T CRANE DRAWING | PEB SHED |

- MONORAIL DETAILSTo create a monorail drawing connected to a concrete beam,… Read more: MONORAIL DETAILS

- Lifting Padeye DesignPadeye is a plate or attachment point commonly used in… Read more: Lifting Padeye Design

- Corbel Design and DetailsDESIGN OF CORBEL A corbel is a short cantilever used… Read more: Corbel Design and Details

- BEHAVIOUR OF STEEL CHIMNEY UNDER DYNAMIC LOADINGSIntroducing Steel Chimneys or Stack The behavior of steel chimneys… Read more: BEHAVIOUR OF STEEL CHIMNEY UNDER DYNAMIC LOADINGS

- DESIGN OF WIND PRESSURE AS PER EN 1991-1-4The calculation for wind load as per EN 1991-1-4 for a gas plant located in a terrain category I includes parameters such as a fundamental basic wind velocity of 32.30 m/s, a directional factor and season factor of 1.00 each, and various terrain factors and roughness lengths. Wind turbulence intensity and peak velocity pressure vary with height.

- Grade Slab DetailsPaving or Grade slab Details A grade slab, also known… Read more: Grade Slab Details

- Resort Cottage PlanDesigning a cottage plan involves creating a cozy, functional, and… Read more: Resort Cottage Plan

- CONCRETE BATCHING PLANT ARRANGEMENTA well-designed batching plant arrangement ensures efficient concrete production, safety,… Read more: CONCRETE BATCHING PLANT ARRANGEMENT

- LOAD COMBINATIONS NBCC 2023LOAD COMBINATIONS CANADIAN CODE NBCC 2023 The National Building Code… Read more: LOAD COMBINATIONS NBCC 2023

- STEEL SHED DRAWING1. Plan View (Top View): Outline of the Shed: Show… Read more: STEEL SHED DRAWING

- Plumbing DrawingCreating a plumbing scheme drawing involves outlining the entire plumbing… Read more: Plumbing Drawing

- Pre Engineered Building Design Specification IS CodePre-Engineered Building PEB PEB stands for Pre-Engineered Building. It refers… Read more: Pre Engineered Building Design Specification IS Code

- BATHROOM FIXTURES AND FITTINGS – European Closet, Urinal & Wash BasinBATHROOM FIXTURES AND FITTINGS European Closet – fitting dimensions For… Read more: BATHROOM FIXTURES AND FITTINGS – European Closet, Urinal & Wash Basin

- Design of Pipe Support Foundation CalculationDesign of Pipe Support Foundation Calculation Piping Input: GA and… Read more: Design of Pipe Support Foundation Calculation

- Design of Concrete Anchor BlocksSTATIC ANALYSIS & DESIGN OF PIPE ANCHOR BLOCK FOUNDATION DESIGN… Read more: Design of Concrete Anchor Blocks

- PEB Shed DrawingPEB – Industrial standard architectural drawing with all details.

Related Posts: