Pre-Engineered Building PEB

PEB stands for Pre-Engineered Building. It refers to a building system where components are designed and fabricated in a factory, then transported to the site for assembly. This method is widely used in the construction of industrial buildings, warehouses, commercial complexes, and other structures requiring large open spaces.

Key Features of PEB:

- Efficiency: Components are manufactured to precise specifications, reducing waste and ensuring consistency.

- Speed of Construction: Since the components are pre-fabricated, the assembly on-site is faster compared to traditional construction methods.

- Cost-Effective: Reduced construction time and material wastage lead to lower overall costs.

- Flexibility: PEBs can be easily expanded or modified, making them adaptable to changing needs.

- Durability: Made with high-quality steel, PEBs are strong and resistant to weather conditions, termites, and other environmental factors.

- Design Versatility: They can be designed to meet various aesthetic and functional requirements, including architectural finishes and integrated systems.

Applications of PEB:

- Industrial Sheds

- Warehouses

- Factories

- Commercial Buildings

- Offices

- Schools

- Sports Halls

- Aircraft Hangars

Components of PEB:

- Primary Frames: The main load-bearing components usually made of steel I-beams.

- Secondary Frames: Purlins, girts, and eave struts that provide additional support.

- Roof and Wall Panels: Pre-fabricated metal sheets or insulated panels.

- Accessories: Includes doors, windows, vents, skylights, and other elements that enhance functionality and aesthetics.

Benefits of PEB:

- Reduced Construction Time: Pre-engineered components mean quicker assembly.

- Lower Maintenance: High-quality materials require less maintenance.

- Energy Efficiency: Insulated panels and reflective roofing can enhance energy efficiency.

- Environmentally Friendly: Reduced material wastage and the potential for recycling components.

PEBs are an excellent solution for projects requiring rapid construction, flexibility, and cost-efficiency.

Categories

- 3D HOUSE DESIGN (18)

- Civil and Structural Design Calculations (38)

- Commercial Plans (9)

- East Facing House Plans (14)

- Engineering Concepts – Civil & Structural (143)

- Excel Spreadsheets (17)

- Free Downloads (12)

- House Plans (51)

- Industrial standards (60)

- North Facing House Plans (15)

- South Facing House Plans (11)

- West Facing House Plans (7)

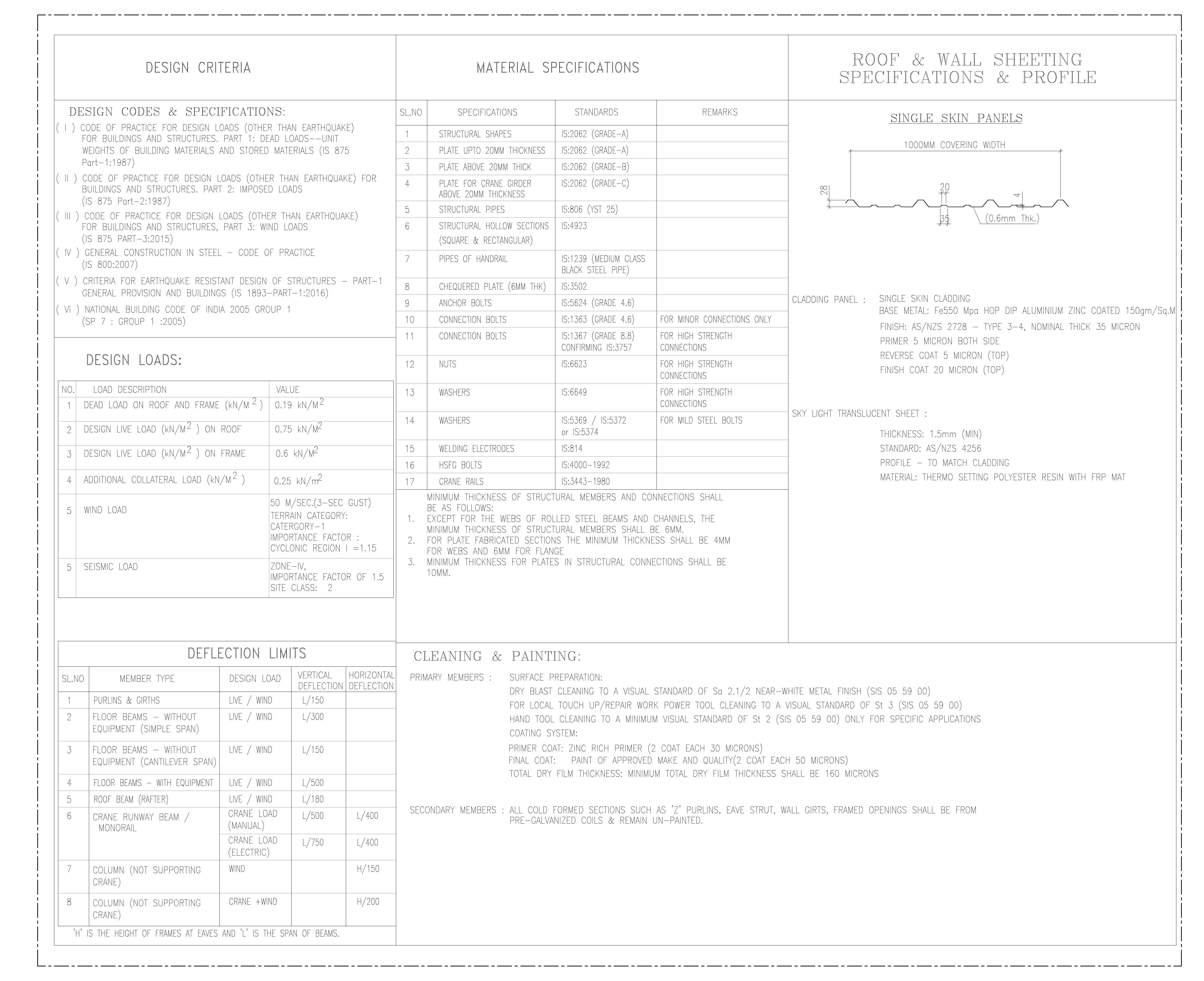

Pre-Engineered Buildings (PEBs) are designed and fabricated to precise specifications that ensure quality, efficiency, and durability. Here are some key specifications and components involved in PEB construction:

- Primary Frame

- Material: High-grade steel (e.g., ASTM A572 Grade 50 or equivalent).

- Components: Columns, rafters, and other primary structural members.

- Fabrication: Welded or hot-rolled sections designed to bear the main loads.

- Secondary Frame

- Material: Cold-formed steel.

- Components: Purlins, girts, eave struts, and bracing.

- Function: Provides additional support to the primary frame and distributes loads.

- Roof and Wall Panels

- Material: Galvanized or pre-painted steel sheets, typically of 26 to 22 gauge (0.4 to 0.8 mm thick).

- Types: Single skin panels or insulated sandwich panels for thermal efficiency.

- Coating: Galvalume or color-coated for corrosion resistance and aesthetics.

- Fasteners and Connections

- Bolts: High-strength bolts (e.g., ASTM A325 or equivalent) for primary frame connections.

- Screws: Self-drilling, self-tapping screws for panel attachment.

- Welds: Where necessary, performed according to AWS (American Welding Society) standards.

- Foundations and Anchor Bolts

- Foundation: Reinforced concrete designed to support the load of the structure.

- Anchor Bolts: Embedded in the foundation to secure the steel structure.

- Design Codes and Standards

- Structural Design: Conforms to international standards such as AISC (American Institute of Steel Construction) or MBMA (Metal Building Manufacturers Association).

- Wind Load: Designed to withstand wind speeds as per local building codes (e.g., ASCE 7-10).

- Seismic Load: Consideration of seismic zone requirements as per local codes.

- Insulation

- Types: Fiberglass, foam, or rock wool.

- Purpose: Enhances energy efficiency and provides thermal and acoustic insulation.

- Doors and Windows

- Material: Steel or aluminum frames with glass, polycarbonate, or metal infill.

- Types: Roll-up doors, sliding doors, personnel doors, fixed or operable windows.

- Accessories

- Ventilation: Ridge vents, louvers, and exhaust fans.

- Natural Lighting: Skylights and translucent panels.

- Gutters and Downspouts: For efficient rainwater drainage.

- Surface Treatment

- Primer: Anti-corrosive primer applied to steel components.

- Finish: Topcoat paint for additional protection and aesthetics.

- Installation

- Erection: Conducted by trained professionals using cranes, hoists, and other lifting equipment.

- Quality Control: Regular inspections to ensure adherence to design specifications and safety standards.

- Optional Features

- Mezzanines: Intermediate floors for additional space.

- Partitions: Internal walls for separate areas within the building.

- Cranes: Overhead cranes for industrial applications.

By following these specifications, Pre-Engineered Buildings provide a reliable and efficient construction solution tailored to various needs and applications.

Recent Posts

- ASCE 7-16 Wind Load on Buildings and Structures

- Column Buckling

- Moody Chart | Moment Reactions for Rectangular Plates |

- Test Pile Drawing Calculation & Guidelines

- Commercial Shop Plan

- Shop Floor Plan

- HOUSE PLAN WITH SHOP 40 x 60 | SOUTH FACING |

- Wind Load Calculation as per Australian Code (AS/NZS 1170.2:2021)

- HOUSE PLAN 30 X 45 | EAST FACING | INTERIOR HOUSE DESIGN |

- HOUSE PLAN 60 x 40 | EAST FACING | APARTMENT TYPE |

- Standard Road Details

- DG Building Architectural Plan & Finishing Schedule

- AMAZING TV UNIT IDEAS 90+ MODELS

- HOUSE PLAN 60 x 50 | EAST FACING |

- Technical Details for Wash Basin Section and Elevation

- Tender Technical Specification for Plumbing and Sanitary works

- HOUSE PLAN 25 x 50 | SOUTH FACING |

- HOUSE PLAN 60 x 45 | SOUTH FACING |

- Fencing Gate Details and Requirements

- Fencing Layout and Details For Transformer Area

- Fencing with Angle Post and Pipe Post Details & Arrangements

- Civil Engineering Formula Book | Pocket Guide pdf Free download |

- HOUSE PLAN 35 x 60 | WEST FACING |

- Transformer Foundation with Soak Pit Layout and Details

- Grating Standard Details and Specifications

- Chequered Plate Standard Details

- Handrail Details for Steel Structural Floors

- Cable Pull Pit Requirements and Details

- Laboratory Building Plan and Architecture Details

- Structural Bolt Details Types Grades and Applications

- HOUSE PLAN 40 x 60 | NORTH FACING |

- Finishing Schedule Drawing for Doors, Windows, and Rolling Shutters

- Workshop Building Architectural Layout

- Calculation of Foundation Bearing Capacity as per IS 6403 – 1981

- Terzaghi’s Bearing Capacity Calculation For Foundations

- DESIGN AND CONSTRUCTION METHOD OF MULTISTORY CONCRETE BUILDINGS

- HOUSE PLAN 60 x 60 | SOUTH FACING |

- Civil Structural Engineering Interview Questions pdf Free Download

- Civil Structural Engineering Interview Questions

- HOUSE PLAN 60 x 30 | EAST FACING |

- HOUSE PLAN 28 x 31 | WEST FACING |

- SHEAR FORCE AND BENDING MOMENT DIAGRAMS WITH FORMULA

- HOUSE PLAN 43 x 66 | SOUTH FACING |

- Canadian Code Seismic Calculation Example

- Weathering Course in RCC Roof

- Rolling Shutter Fixing Detail with RCC Beam

- HOUSE PLAN 35 x 50 | SOUTH FACING |

- APARTMENT PLAN 53 x 62 | EAST & WEST Facing |

- Duct Bank Details and Pipe Sleeves Details

- Handrail Details | Construction Methods and Types of Handrail |

- Details of Ramp

- Design Calculation of Steel Shelter – AISC 360

- Cage Ladder Specification and Detail Drawing

- Staircase Ideas 40+

- Vertical Vessel Foundation Design

- Effective Length for RCC Columns

- DESIGN OF SLABS AS PER IS456

- Design of Staircase Waist Slab

- Monorail Beam Design

- HOUSE PLAN 35 x 50 | SOUTH FACING |

- Concrete Beam Design as per Canadian Code (CSA A23.3-19)

- Wind Load Calculation as per Canadian Code | NBCC 2020 |

- Fencing Detail Drawing

- HOUSE PLAN 40 x 60 | NORTH FACING |

- HOUSE PLAN 60 x 30 | SOUTH FACING |

- RCC Fencing Post Details

- HOUSE PLAN 30 x 40 | NORTH FACING |

- HOUSE PLAN 45 x 45 | WEST FACING |

- HOUSE PLAN 40 x 40 | WEST FACING |

- HOUSE PLAN 30 x 50 | SOUTH FACING |

- Modern House Front Elevation Design

- Transformer Foundation Design

- Gypsum Board False Ceiling Installation

- Box Culvert Design

- Design of Anchor Reinforcement in Concrete Pedestals

- Wind Load Calculation for Pipe Rack

- Apartment House Plan | West Facing 60 x 60 |

- kitchen marble design 30+

- Wind Load Calculation as per IS 875 Part 3 2015

- DESIGN BASIS FOR CIVIL AND STRUCTURAL

- General Specification for Civil and Structural Works

- Green Building

- Fireproofing Details

- Response Spectrum Analysis in STAAD pro

- SHELTER WITH 25T CRANE DRAWING | PEB SHED |

- HOUSE PLAN 20 x 60 | WEST FACING |

- MONORAIL DETAILS

- WEST FACING HOUSE PLAN 50 x 40 | DUPLEX TYPE |

- Side Face Reinforcement as per ACI & IS code

- HOUSE PLANS

- HOUSE PLAN 35 x 50 | EAST FACING |

- HOUSE PLAN 25 x 60 | NORTH FACING |

- HOUSE PLAN 35 x 50 | NORTH FACING |

- Design of Cold-Formed Steel Structures as Per IS 801

- HOUSE PLAN 30 x 40 | EAST FACING |

- HOUSE PLAN 30 x 40| NORTH FACING |

- HOUSE PLAN 20 x 40 | NORTH FACING |

- Lifting Padeye Design

- Corbel Design and Details

- DYNAMIC ANALYSIS USING RESPONSE SPECTRUM ANALYSIS

- Building Load Calculation

- Deep Excavations

- Bathroom Tiles Designs Ideas 50+

- Wooden Main Door Ideas 40+

- Gate Design Ideas 60+

- Structural Design of working pile

- Design of Gantry Girder

- Modern Kitchen Interior Idea Photos 26+

- BEHAVIOUR OF STEEL CHIMNEY UNDER DYNAMIC LOADINGS

- Church Design Drawing

- Seismic Load Calculation as per ASCE 7-16

- 33×66 North Facing Ground Floor Plan with Vastu

- DESIGN OF WIND PRESSURE AS PER EN 1991-1-4

- Best 3D House Elevation Design G+1

- House Plan with Photos | Architect Detail Drawing |

- Trench Details

- PRECAST COVER SLAB DETAILS

- Grade Slab Details

- Resort Cottage Plan

- CONCRETE BATCHING PLANT ARRANGEMENT

- LOAD COMBINATIONS NBCC 2023

- STEEL SHED DRAWING

- Plumbing Drawing

- Pre Engineered Building Design Specification IS Code

- SMALL HOUSE PLAN 28 x 40 | NORTH FACING |

- DESIGN OF PIPERACK STRUCTURE

- BATHROOM FIXTURES AND FITTINGS – European Closet, Urinal & Wash Basin

- DUPLEX HOUSE PLAN 30 x 30 | EAST FACING |

- HOUSE PLAN 29 x 44 | EAST FACING | DUPLEX HOUSE

- Design of Pipe Support Foundation Calculation

- FLAT SLAB DESIGN AND DETAILING

- DIRECT ANALYSIS METHOD AISC 360-05 AND ITS IMPLEMENTATION IN STAAD

- PILE FOUNDATION | TYPE OF PILES | TEST METHODS AND SITE EXECUTION |

- HOUSE PLAN 38 x 58 | BEST EAST FACING | HOME THEATER

- Front Elevation Design 30+

- Design of Concrete Anchor Blocks

- HOUSE PLAN WITH OFFICE AT GROUND FLOOR 27 x 88 | NORTH FACING |

- Design of Shear Key in Base Plate as per IS Code

- HOUSE PLAN 45 x 40 | BEST NORTH FACING BUILDING PLAN |

- BANQUET HALL PLAN 40 x 60 | NORTH FACING |

- MARRIAGE HALL PLAN 33 x 77 | SOUTH FACING |

- COMMERCIAL PLAN 48 x 40 | NORTH FACING |

- APARTMENT TYPE HOUSE PLAN 30 x 80 | EAST FACING | 3BHK

- APARTMENT PLAN 40×50 | EAST FACING | 3BHK |

- Concrete Mix Design Calculations

- PEB Shed Drawing

- HOUSE PLAN 40 x 46 | NORTH FACING |

- DEVELOPMENT LENGTH OF REBAR