Designing working piles according to IS 2911 (Part 1 to 4) standards involves specific guidelines to ensure the safe and effective construction of piles used as foundations for various types of structures. IS 2911 is the Indian Standard for the design and construction of pile foundations. The standard is divided into multiple parts, each addressing different types of piles and their construction methods.

Here’s a step-by-step guide to designing working piles as per IS 2911:

1. Understanding the Types of Piles (Refer to IS 2911 Parts 1 to 4)

-

- IS 2911 (Part 1): Driven cast in-situ concrete piles

-

- IS 2911 (Part 2): Bored cast in-situ concrete piles

-

- IS 2911 (Part 3): Driven precast concrete piles

-

- IS 2911 (Part 4): Large-diameter bored piles

2. Preliminary Data Collection

-

- Soil Investigation: Conduct a detailed soil investigation to determine the soil type, bearing capacity, and stratification.

-

- Load Data: Obtain the structure’s total load, including dead loads, live loads, wind loads, and seismic loads.

-

- Environmental Conditions: Consider groundwater levels, chemical composition of soil (for corrosive conditions), and any other environmental factors.

3. Pile Type Selection

-

- Based on the soil conditions and load requirements, select an appropriate type of pile (driven, bored, or precast). For example, driven piles are suitable for sandy soils, while bored piles are more suitable for clayey soils.

-

- Consider accessibility and site constraints when selecting the pile type.

4. Design Considerations

-

- Load Capacity: Calculate the ultimate load-bearing capacity of the pile considering both end-bearing and skin friction capacities.

For End-Bearing Capacity:

- Load Capacity: Calculate the ultimate load-bearing capacity of the pile considering both end-bearing and skin friction capacities.

Qb=Ab⋅qb

Where:

-

- Qb = Ultimate end-bearing capacity

-

- Ab = Area of pile base

-

- qb = Unit end-bearing resistance

Qs=∑(As⋅fs)

Where:

-

- Qs = Ultimate skin friction capacity

-

- As = Surface area of pile shaft

-

- fs = Unit skin friction

-

- Safety Factors: Apply safety factors as recommended in IS 2911. Typically, a factor of safety (FOS) of 2.5 to 3.0 is used for pile capacity.

-

- Group Action: If piles are used in a group, consider group effects and spacing (usually, a spacing of 2.5 to 3 times the pile diameter is used to reduce interaction effects).

-

- Settlement Analysis: Ensure that the total settlement and differential settlement are within permissible limits.

5. Structural Design of Pile

-

- Pile Diameter and Length: Based on load calculations, select the pile diameter and length.

-

- Reinforcement Design: Design the reinforcement cage as per IS 456 (Code of Practice for Plain and Reinforced Concrete).

-

- Minimum longitudinal reinforcement: 0.4% of the cross-sectional area of the pile.

-

- Minimum lateral reinforcement (ties or spirals) should be provided to ensure adequate confinement and resistance to lateral loads.

-

- Reinforcement Design: Design the reinforcement cage as per IS 456 (Code of Practice for Plain and Reinforced Concrete).

-

- Concrete Grade: Select the concrete grade based on exposure conditions and structural requirements, typically not less than M20 grade for piles.

6. Pile Cap Design

-

- Design the pile cap to distribute loads from the superstructure to the piles. Ensure that the pile cap is thick enough to prevent punching shear failure.

-

- Reinforcement in the pile cap should be provided based on the bending and shear forces obtained from the analysis.

7. Load Testing

-

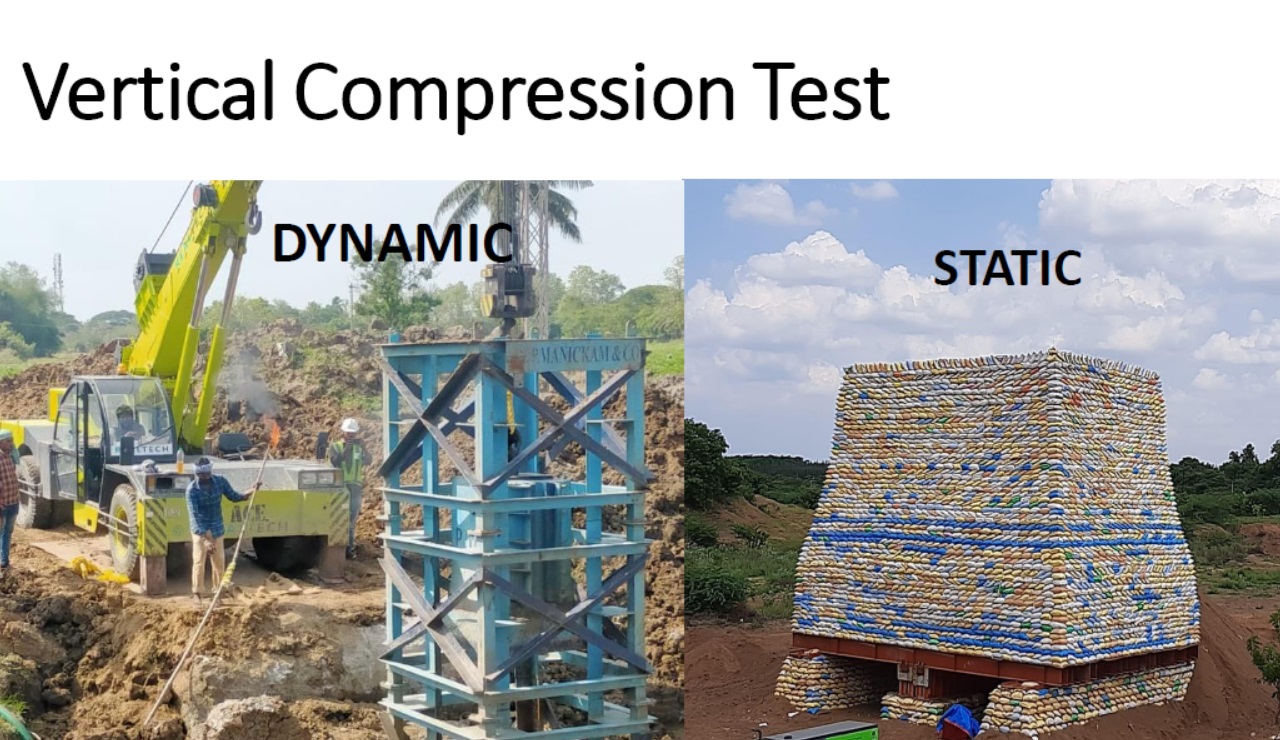

- Initial and Routine Load Tests: Conduct initial load tests to verify the pile design and routine load tests to confirm the working pile’s capacity as per IS 2911 guidelines.

-

- Static Load Test: The test load should generally be 1.5 times the design working load.

8. Construction and Quality Control

-

- Supervision: Ensure strict supervision during pile installation to maintain alignment, depth, and verticality.

-

- Curing: Proper curing of concrete piles is essential to achieve the required strength.

-

- Non-Destructive Testing: Use methods like pile integrity tests (PIT) or sonic tests to ensure pile quality and detect defects.

9. Documentation and Record Keeping

-

- Maintain detailed records of pile installation, test results, and construction methods used. This documentation is crucial for future references and certifications.

10. Compliance with IS Codes

-

- Ensure the design and construction comply with the relevant parts of IS 2911, IS 456 (for concrete), and any other applicable local codes and regulations.

Conclusion

Designing working piles according to IS 2911 involves understanding the site conditions, selecting the appropriate type of pile, calculating load capacities, and adhering to safety and design standards. Each step requires careful attention to detail to ensure the safety and longevity of the structure supported by the pile foundation. For complex projects, consulting with experienced geotechnical and structural engineers is recommended

Refer standard design calculation below

Categories

- 3D HOUSE DESIGN (21)

- Civil and Structural Design Calculations (43)

- Commercial Plans (9)

- East Facing House Plans (14)

- Engineering Concepts – Civil & Structural (160)

- Excel Spreadsheets (18)

- Free Downloads (20)

- House Plans (53)

- Industrial standards (70)

- North Facing House Plans (15)

- South Facing House Plans (13)

- West Facing House Plans (8)

Recent Posts

- Loads and Load Combinations as per AS/NZS 1170.0 2002

- Design of Pump Foundation Dynamic and Static Analysis

- HOUSE PLAN 60 X 40 | WEST FACING |

- Latest Staircase Handrail Design Ideas 40+

- HOUSE PLAN 50 X 50 | SOUTH FACING |

- Electrical Layout For Residential Building

- HOUSE PLAN 29 X 56 | SOUTH FACING |

- Rain Water Gutter and Down Take Systems

- Stormwater Drainage Calculation

- Structural Engineering Design Criteria – American Codes and Standards

- Anchor Bolts Length as per ACI 318-14

- Insert Plate Details & Drawing – Embedded in Concrete Structures

- JOURNAL PAPER GUIDELINES FOR ACSE

- Anchor Bolt Details and Drawing – Embedded in Concrete

- Staircase Layout and Details

- Guard House Layout and Details

- Pump Shed Structural Steel Drawing

- ASCE 7-16 Wind Load on Buildings and Structures

- Column Buckling

- Moody Chart | Moment Reactions for Rectangular Plates |

- Test Pile Drawing Calculation & Guidelines

- Commercial Shop Plan

- Shop Floor Plan

- HOUSE PLAN WITH SHOP 40 x 60 | SOUTH FACING |

- Wind Load Calculation as per Australian Code (AS/NZS 1170.2:2021)

- HOUSE PLAN 30 X 45 | EAST FACING | INTERIOR HOUSE DESIGN |

- HOUSE PLAN 60 x 40 | EAST FACING | APARTMENT TYPE |

- Standard Road Details

- DG Building Architectural Plan & Finishing Schedule

- AMAZING TV UNIT IDEAS 90+ MODELS

- HOUSE PLAN 60 x 50 | EAST FACING |

- Technical Details for Wash Basin Section and Elevation

- Tender Technical Specification for Plumbing and Sanitary works

- HOUSE PLAN 25 x 50 | SOUTH FACING |

- HOUSE PLAN 60 x 45 | SOUTH FACING |

- Fencing Gate Details and Requirements

- Fencing Layout and Details For Transformer Area

- Fencing with Angle Post and Pipe Post Details & Arrangements

- Civil Engineering Formula Book | Pocket Guide pdf Free download |

- HOUSE PLAN 35 x 60 | WEST FACING |

- Transformer Foundation with Soak Pit Layout and Details

- Grating Standard Details and Specifications

- Chequered Plate Standard Details

- Handrail Details for Steel Structural Floors

- Cable Pull Pit Requirements and Details

- Laboratory Building Plan and Architecture Details

- Structural Bolt Details Types Grades and Applications

- HOUSE PLAN 40 x 60 | NORTH FACING |

- Finishing Schedule Drawing for Doors, Windows, and Rolling Shutters

- Workshop Building Architectural Layout