Concrete Beam Design as per Canadian Code (CSA A23.3-19)

The design of concrete beams in Canada is governed by CSA A23.3-19: Design of Concrete Structures, which provides guidelines for strength, serviceability, and durability of reinforced concrete elements. Below is a step-by-step approach to designing a concrete beam according to the Canadian code.

1. Key Parameters for Beam Design

Material Properties:

- Concrete Strength (f′c):

- Typically ranges from 20 MPa to 50 MPa.

- Reinforcement Steel (fy):

- Yield strength: 400 MPa or 500 MPa (common for rebar in Canada).

Load Considerations:

- Factored Loads:

- Factored dead load (Df ) and factored live load (Lf).

-

Load combinations as per CSA A23.3-19 Clause 8.1:

- 1.25D + 1.5L (for beams).

- Self-weight:

- Concrete density: 24 kN/m3

2. Assumptions for Flexural Design

Cross-Sectional Properties:

- Rectangular beam: width (b), effective depth (d).

- Neutral axis depth (c): determined iteratively during the design.

Assumptions:

- The concrete in tension is neglected.

- Steel reinforcement resists all tensile forces.

- Compression is resisted by concrete in the compression zone.

3. Flexural Strength Design

Step 1: Nominal Moment Capacity (Mn)

The nominal moment capacity for a singly reinforced beam is given by:

Mn= ϕ ⋅ As ⋅ fy ⋅ (d−a/2)

Where:

- As : Area of tensile reinforcement (As = n ⋅ π ⋅ db2/4).

- a : Depth of equivalent rectangular stress block (a = β1 ⋅c ).

- β1: Factor based on f′c (from CSA Table 10.2.1).

Step 2: Solve for Reinforcement Area (As)

For a given factored moment (Mu):

As = Mu ϕ ⋅ fy ⋅ (d−a/2)

Where:

- ϕ : Resistance factor (typically 0.85 for flexural design).

- Mu : Factored bending moment.

4. Shear Design

Shear Strength (Vc and Vs)

The shear resistance (Vr) is the sum of contributions from concrete (Vc) and stirrups (Vs):

Vr = ϕ ⋅ (Vc + Vs)

Concrete Contribution (Vc ):

Vc = 0.166 ⋅ f′c ⋅ b ⋅ d

- Stirrups Contribution (Vs):

Vs = Av ⋅ fy ⋅ ds

Where:

- Av : Area of stirrups.

- S: Stirrup spacing.

5. Serviceability Checks

Deflection Control:

- Ensure span-to-depth ratio satisfies serviceability requirements.

- CSA provides limits based on beam type and loading.

Crack Control:

- Reinforcement spacing must ensure crack widths are within acceptable limits.

6. Durability Considerations

Minimum Reinforcement:

- Provide minimum reinforcement to prevent sudden failure:

As ≥ 0.2 ⋅ b ⋅ d/fy

Clear Cover:

-

Ensure adequate concrete cover for durability:

- 25 mm: Interior beams.

- 40 mm : Exterior beams.

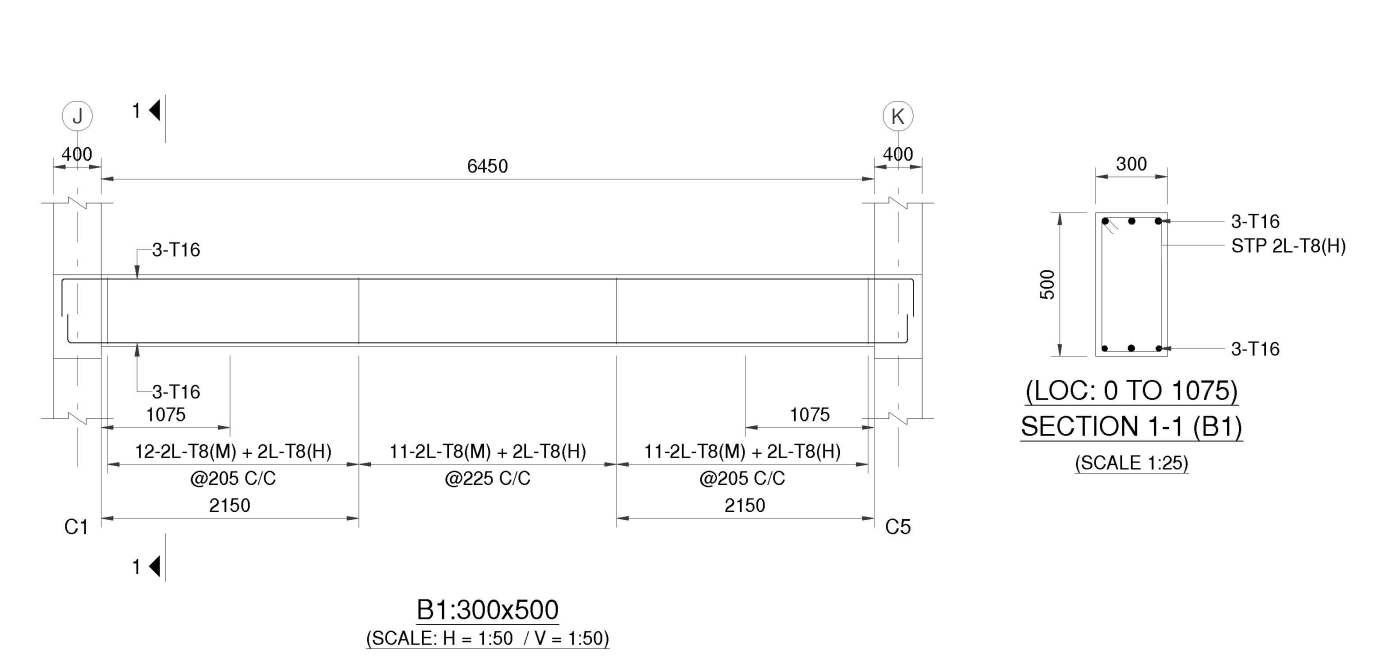

Example: Design a Rectangular Beam

Given Data:

- Factored moment (Mu ): 150 kNm

- Beam dimensions: b=300 mm,d=500 mm

- f′c=30 Mpa, fy=400 Mpa

Step 1: Calculate a

β1=0.85 (from CSA Table 10.2.1 for f′c=30)

Assume a ≈ 0.1d =50 mm

Step 2: Calculate As

Substitute values into the moment formula:

As= Mu

Φ ⋅ fy ⋅ (d−a/2)

As = 150,0000

0.85 ⋅ 400 ⋅ (500−25) ≈ 880 mm2

Provide 3 ϕ16 mm3

Step 3: Check Shear

Use Vc and Vs formulas for shear design and ensure Vr≥Vu

This process ensures the beam complies with CSA A23.3-19 for strength, serviceability, and durability. Here’s a detailed guide and example for the design of a rectangular concrete beam as per CSA A23.3-19 standards:

Step-by-Step Concrete Beam Design Process

1. Problem Statement:

Design a simply supported concrete beam to resist the following loads:

- Span (L): 6 meters

- Factored loads:

- Dead load (Df): 10 kN/m

- Live load (Lf): 15 kN/m

- Material properties:

- Concrete compressive strength (fc′): 30 MPa

- Steel yield strength (fy): 400 MPa

2. Preliminary Section Dimensions

Choose approximate dimensions for the beam based on the span-to-depth ratio:

Effective Depth (d)= Span

16 to 20

Assume b=300 mm, d=500 mm

3. Flexural Design

Step 1: Factored Moment (Mu)

- Total factored load per unit length (wu):

Wu = 1.25Df + 1.5Lf = 1.25(10) + 1.5(15)=31.25 kN/m

Maximum factored moment (Mu) for a simply supported beam:

Mu = wuL2 / 8 = 31.25⋅628 = 140.63 kNm

Step 2: Calculate Depth of Stress Block (a)

Using the stress block formula:

a=β1c

Where:

- β = 0.85

- c : Distance from the extreme compression fiber to the neutral axis.

Step 3: Reinforcement Area (As)

The nominal moment capacity is given by:

Mn = As . fy (d−a/2)

Rearrange to solve for As:

As=Mu / ϕ.fy. (d − a/2)

Substitute:

- ϕ=0.85 (resistance factor for flexure)

- Assume a=50 mm

As= 140.63 ⋅ 106

0.85 ⋅ 400 ⋅ (500−25) ≈880.75 mm2

Provide 3 bars of 16 mm diameter reinforcement:

As= 3⋅ π / 4 ⋅ (16)2=904.78 mm2

This satisfies the required As

4. Shear Design

Step 1: Factored Shear Force (Vu)

The maximum shear force at the support is:

Vu = wu . L/ 2 =(31.25 ⋅ 6 / 2) = 93.75 kNV_

Step 2: Shear Resistance (Vr)

The total shear resistance is:

Vr = ϕ ⋅ (Vc+Vs)

- Concrete Contribution (Vc):

Vc = 0.166 ⋅ fc′ . b ⋅ d

Vc = 0.166 ⋅ 30 ⋅ 300 ⋅ 500 = 216.1 KN

- Steel Contribution (Vs): If additional reinforcement is needed:

Vs = Av ⋅ fy ⋅ ds

Where:

- Av : Area of stirrup legs (e.g., 2 ⋅π ⋅102/4 =157 mm2,

- s: Stirrup spacing.

Assume s=200 mms:

Vs=157 ⋅ 400⋅ 500 / 200 ⋅ 1000 = 157 kN/m

5. Deflection Check

For serviceability:

- Check span-to-depth ratio against allowable limits from CSA Table 9.1.

6. Durability and Cover

-

Provide clear cover as per CSA standards:

- 25 mm for interior beams.

- 40 mm for exterior beams.

- Ensure crack control by limiting spacing of tensile steel bars to:

Max spacing=300 mm or less

Summary

- Beam Size: b=300 mm, d=500 mm

- Reinforcement:

- Flexure: 3 ϕ16 mm bars.

- Shear: Stirrups of 2 ϕ10 mm spaced at 200mm.

- Shear Resistance:

- Vc=216.1 kN, Vr=373.1 kN

This ensures the beam satisfies flexural strength, shear resistance, and serviceability as per CSA A23.3-19.

- 3D HOUSE DESIGN (34)

- Civil and Structural Design Calculations (76)

- Commercial Plans (9)

- East Facing House Plans (14)

- Engineering Concepts – Civil & Structural (224)

- Excel Spreadsheets (37)

- Free Downloads (49)

- House Plans (57)

- Industrial standards (91)

- North Facing House Plans (15)

- South Facing House Plans (15)

- West Facing House Plans (9)