Box culvert design according to IRC 6 (Standard Specifications and Code of Practice for Road Bridges, Section II) involves several considerations for structural strength, stability, and durability. Here are the main design bases to consider:

1. Load Considerations

- Dead Load: Weight of the box culvert, including the self-weight of the concrete, parapets, and other permanent structural components.

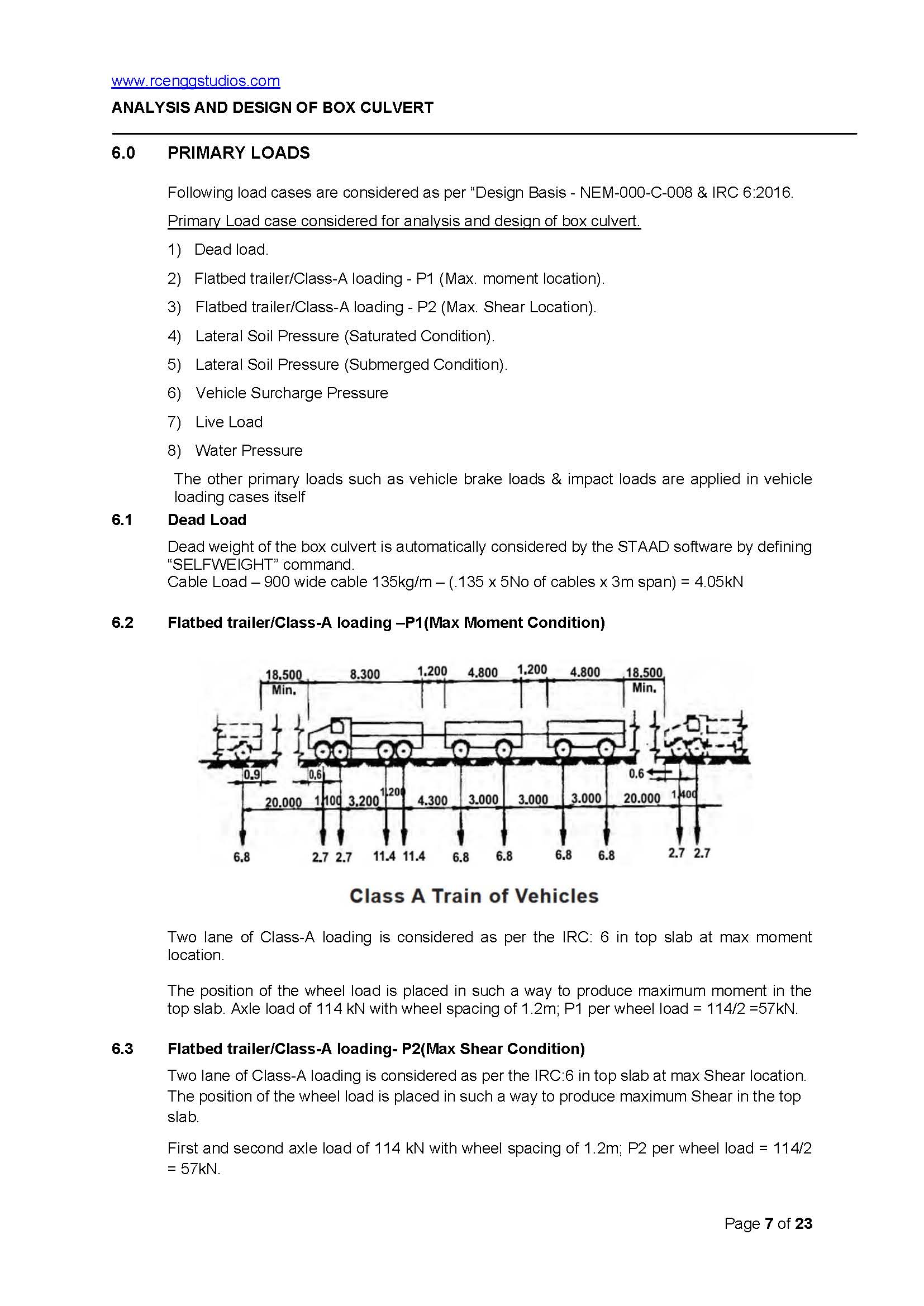

- Live Load: Vehicular load as per IRC 6, generally adopting IRC Class A, AA, or 70R loading, depending on the culvert’s location and importance.

- Impact Load: Apply an impact factor as per IRC 6 if vehicles can travel directly over the culvert, based on the design speed and load class.

- Surcharge Load: Lateral earth pressure due to embankment or backfill material on top of the box culvert.

- Water Load: Hydrostatic pressure exerted by water on the culvert, considering maximum water levels and pressure distributions.

- Earth Pressure: Lateral and vertical earth pressure, depending on soil type, compaction, and depth of the cover.

2. Design Parameters

- Effective Span and Depth: Determine based on the roadway width, hydraulic needs, and site conditions.

- Material Strengths:

- Use minimum M25 grade concrete and Fe 500 steel as specified by IRC standards for durability.

- Reinforcement Detailing: Reinforcement should comply with IRC standards for ductility and resilience against loading.

- Clear Cover: Provide a minimum cover as specified by IRC to protect reinforcement from environmental exposure.

3. Hydraulic Design

- Calculate the hydraulic capacity based on IRC SP 13 to ensure the culvert can handle expected water flows.

- Check for scouring and erosion potential and design to mitigate these effects.

4. Structural Design Checks

- Bending Moment and Shear Force: Calculate moments and shear at various sections (e.g., midspan, supports) using the loads and support conditions. Ensure compliance with bending and shear capacities as per IS 456 and IRC standards.

- Serviceability Checks: Check for deflection, cracking, and durability. IRC specifies crack width limits and deflection limits based on service life requirements.

5. Other Considerations

- Thermal Effects: Design for temperature gradients in areas with significant seasonal temperature variations.

- Durability and Service Life: Select materials and design thicknesses to ensure a long service life with minimal maintenance.

- Construction Joints: Place construction joints according to IRC specifications to accommodate differential settlement and thermal movements.

6. Load Combinations

- Apply various load combinations as per IRC, including:

- Dead Load + Live Load

- Dead Load + Surcharge Load + Live Load

- Water Pressure + Dead Load + Live Load

Example Design Considerations:

- For a 2-lane box culvert, with Class AA loading:

- Top Slab: Designed to resist bending moments due to dead load, live load, and surcharge.

- Walls: Designed for both axial and flexural stress due to earth pressure and surcharge.

- Bottom Slab: Resists uplift pressure and bending due to subgrade reaction.

References

- IRC 6-2017: General Specifications for Loads and Stresses

- IRC 21: For the concrete mix and structural detailing requirements.

- IS 456: For concrete design and reinforcement detailing

Civil Engineering Formula Book | Pocket Guide pdf Free download |

Civil Engineering Formula Book – Essential Reference for Engineers Civil engineering is a vast field…

DEVELOPMENT LENGTH OF REBAR

How to calculate the development length for different grades of concrete as per IS 456?Development…

Handrail Details for Steel Structural Floors

Details and Requirements of Handrails for Steel Structural Floors Handrails are essential for safety and…

HOUSE PLAN 35 x 50 | EAST FACING |

HOUSE PLAN 35 x 50 | EAST FACING | House Plan ground + first floors,…

Fireproofing Details

Fireproofing, also known as fire-resistive protection, is crucial for structural elements in buildings to prevent…