The excel sheet is very simple to use and anyone with basic knowledge of the materials can do mix designing using this sheet, the process of designing of the mixes to be followed;

“Do write the details in the Yellow cells only and do not make edit in other cell as the excel sheet is not protected with password and you can edit anywhere in the sheet, accidental edits in the cells may lead to errors in the mix design sheet due to overriding of formula by values edited by you”

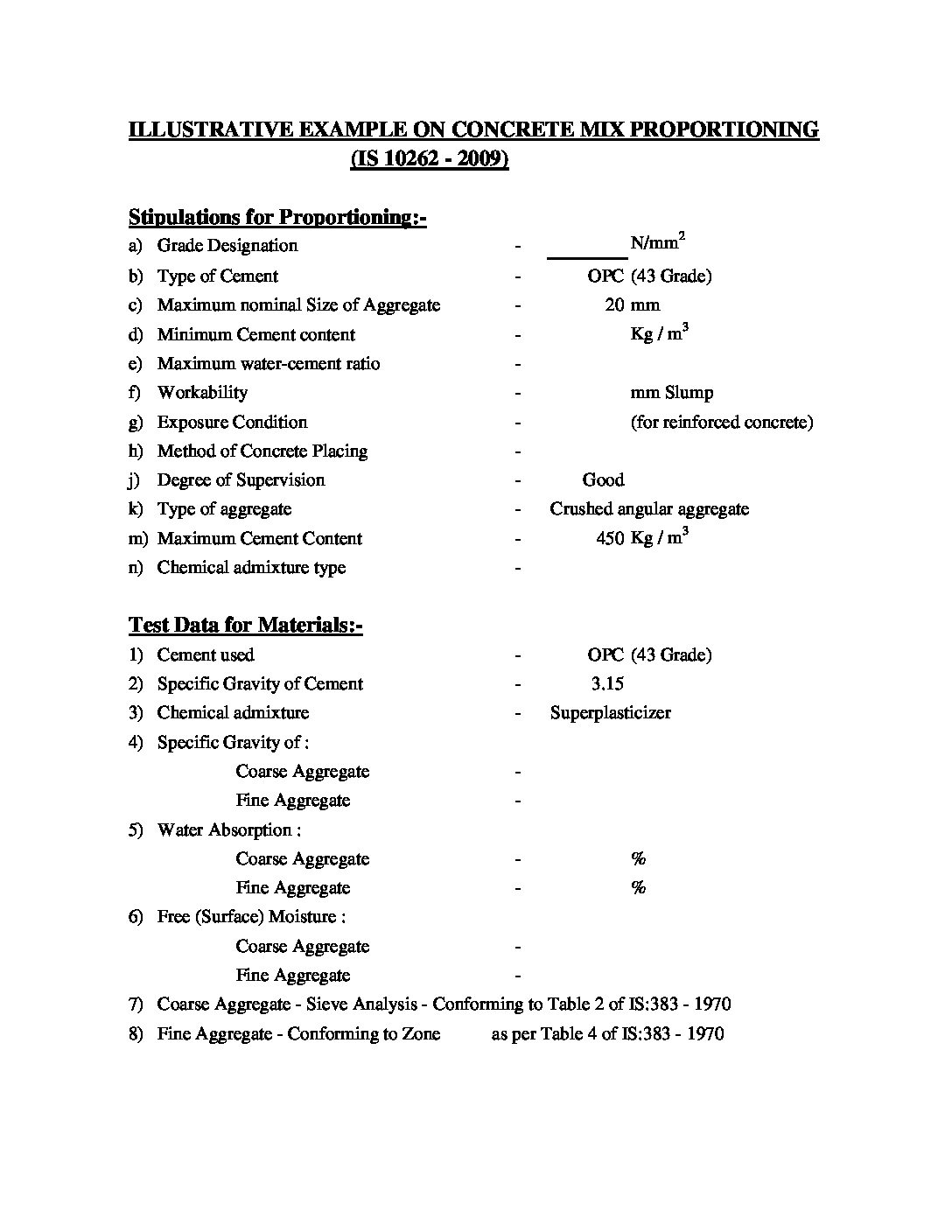

Steps of Mix Design as per IS Method

Step 1: From the known degree of control and the require characteristic strength, determine the SD*

Step 2: Fix the Target Strength from the equation

Target Strength = fck + 1.65 x SD*

Step 3: For the required target strength determine the free water – cement ratio from the curves**

Step 4: The value obtained should be checked with the maximum water – cement ratio*

Step 5: Determine water content in kg per cum of concrete and percentage of sand in total aggregate by absolute weight. Apply correction*** for water content and sand content

Step 6: After determining the water content, go back to step 3 and taking that water – cement ratio, determine the weight of cement.

Step 7: Check the cement content obtained above with that required from the point of durability* and apply correction, if required. Adopt greater of two values.

Step 8: Estimate the % of entrapped air****. The percentage depends upon the degree of compaction. Even after good compaction, there will be some entrapped air in concrete.

Table 8 : IS 456 – 2000

IS 10262

SP 23, Table 36 and Table 6 of IS 10262

Table 3: IS 10262

Reviews

There are no reviews yet.