Paving or Grade slab Details

A grade slab, also known as a ground-bearing slab, is a type of concrete slab that is directly supported by the ground and typically used as the foundation for buildings and other structures. Here are the details for designing and constructing a grade slab:

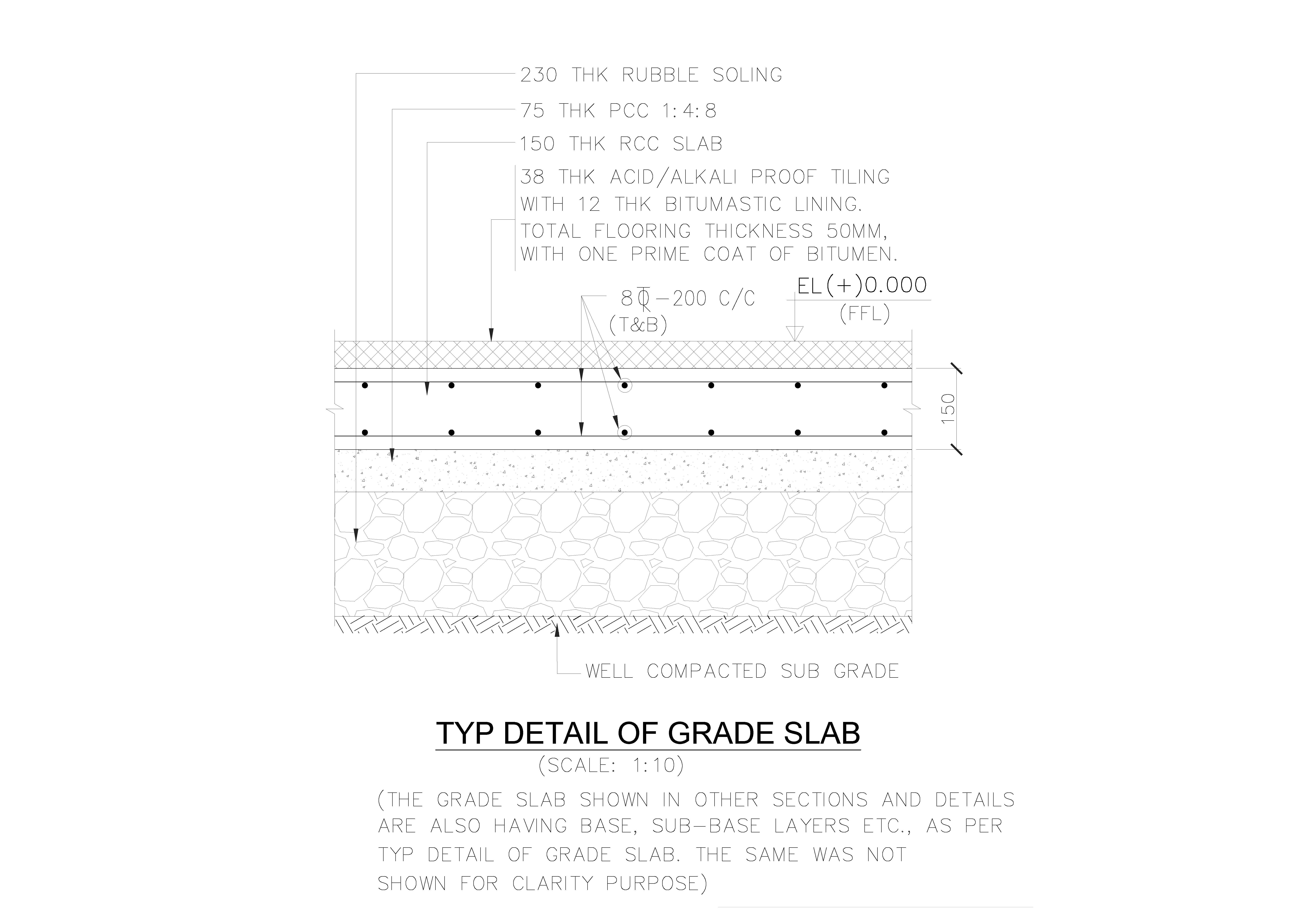

Components and Structure

Subgrade Preparation

- Excavation: Excavate the site to the required depth, removing all vegetation, debris, and unsuitable soil.

- Compaction: Compact the subgrade soil to achieve the desired density and stability. This helps in preventing future settlement and ensures uniform support for the slab.

- Geotextile Fabric (optional): Place a geotextile fabric over the subgrade to prevent soil migration and improve stability.

Subbase Layer

- Material: Typically consists of a layer of compacted granular fill or crushed stone (gravel) with a thickness of 4 to 6 inches.

- Compaction: Ensure thorough compaction of the subbase layer to provide a firm and stable surface for the concrete slab.

Damp-Proof Membrane (DPM) or Vapor Barrier

- Material: A polyethylene sheet or similar material.

- Purpose: Prevents moisture from rising through the slab from the ground, which can damage the concrete and any flooring materials.

- Installation: Lay the DPM over the subbase, ensuring it is continuous and free of punctures. Overlap joints by at least 6 inches and seal them with tape.

Reinforcement

- Material: Welded wire mesh (WWM) or rebar (steel rods).

- Placement: Position the reinforcement within the slab according to structural design specifications. Typically, it is placed on chairs or supports to ensure it is positioned in the middle or top third of the slab thickness.

- Design: The size, spacing, and placement of reinforcement depend on the load requirements and local building codes.

Formwork

- Material: Wood or metal forms.

- Purpose: Defines the shape and size of the slab and holds the concrete in place during curing.

- Installation: Set up the formwork to the required dimensions and ensure it is level and properly supported to withstand the pressure of the wet concrete.

Concrete Pouring

- Mix Design: Use a concrete mix that meets the strength and durability requirements of the project.

- Placing: Pour the concrete within the formwork, starting from one end and working methodically to avoid cold joints.

- Compaction: Use vibrators to compact the concrete and remove air pockets, ensuring a dense and uniform slab.

- Leveling: Use screeds and bull floats to level the surface of the concrete.

Finishing

- Surface Finish: Apply the desired finish to the surface of the concrete, such as a smooth troweled finish, broom finish, or stamped texture.

- Edges: Use edging tools to round off the edges of the slab for a neat appearance and to prevent chipping.

Curing

- Methods: Cure the concrete to maintain moisture and temperature for optimal strength development. Methods include water curing (sprinkling or ponding), covering with wet burlap or plastic sheets, and using curing compounds.

- Duration: Typically cure the concrete for at least 7 days, or as specified by the concrete mix design and project requirements.

Considerations for Grade Slab Construction

- Load Requirements: The thickness and reinforcement of the slab should be designed based on the expected loads (dead loads, live loads, and dynamic loads).

- Soil Conditions: Conduct a soil investigation to determine the bearing capacity and settlement characteristics of the subgrade.

- Expansion Joints: Include expansion joints to accommodate thermal expansion and contraction, especially in large slabs.

- Drainage: Ensure proper site drainage to prevent water accumulation under the slab, which can lead to soil erosion and slab settlement.

- Insulation: In cold climates, consider adding insulation under the slab to prevent frost heave and improve energy efficiency.

Example of a Typical Grade Slab Design

- Subgrade: Compacted soil, leveled and free from organic materials.

- Sub-base: 6 inches of compacted crushed stone or gravel.

- DPM: 6-mil polyethylene sheet, properly sealed at overlaps.

- Reinforcement: #4 rebar spaced 12 inches on center, both ways.

- Concrete: 4 inches thick, M25 mix, placed in one continuous pour.

- Finishing: Smooth trowel finish with a broom texture for slip resistance.

- Curing: Cover with wet burlap for 7 days, keeping the surface moist.

By following these detailed steps and considerations, you can ensure a well-constructed grade slab that provides a strong, durable foundation for your building.

Designing a grade slab to accommodate pipe loads involves considering the various types of loads that the pipes may exert on the slab, including dead loads, live loads, and potential dynamic loads. Here’s a detailed guide on how to approach the design:

Types of Loads

- Dead Loads

- Live Loads

- Dynamic Loads

- Thermal Loads

- Impact Loads

Design Considerations

- Pipe Material and Diameter

- Load Distribution

- Slab Thickness

- Reinforcement

- Subgrade and Sub-base Preparation

- Support and Anchoring

- Load Combinations

Detailed Steps for Designing a Grade Slab for Pipe Loads

1. Pipe Material and Diameter

- Pipe Material: Determine the material of the pipes (e.g., steel, PVC, concrete) as it influences the load.

- Diameter and Wall Thickness: Larger and thicker pipes will exert more load.

2. Load Distribution

- Uniform Load: Calculate the uniform load distributed over the slab area.

- Point Load: Consider point loads if pipes are supported at specific points.

3. Slab Thickness

- Determination: Based on load calculations, determine the required slab thickness. Typically, slabs range from 4 to 8 inches in thickness, but may need to be thicker for heavy loads.

- Design Standards: Use standards like ACI (American Concrete Institute) or relevant local codes to guide thickness and reinforcement requirements.

4. Reinforcement

- Reinforcement Bars (Rebar): Use rebar to provide tensile strength to the slab. Typical rebar sizes are #4 or #5, spaced 12 inches on center, both ways.

- Placement: Ensure rebar is placed in the upper and lower thirds of the slab thickness for maximum effectiveness.

5. Subgrade and Sub-base Preparation

- Compaction: Ensure the subgrade is well-compacted to provide a stable foundation.

- Granular Base: Add a layer of compacted granular material (e.g., crushed stone) to improve load distribution and drainage.

6. Support and Anchoring

- Pipe Supports: Use appropriate pipe supports and anchors to distribute loads and reduce stress on the slab.

- Expansion Joints: Include expansion joints to accommodate thermal expansion and contraction of both the slab and the pipes.

7. Load Combinations

- Dead Load: Weight of the pipes and the slab itself.

- Live Load: Any additional loads such as vehicles or equipment.

- Dynamic Load: Consider loads due to fluid movement within the pipes.

- Impact Load: Potential loads from dropped objects or equipment on the slab.

Example Calculation for Pipe Loads on a Grade Slab

Pipe Specifications: Steel pipe, 12 inches in diameter, filled with water.

- Weight of steel pipe per foot: 20 lbs

- Weight of water per foot: 40 lbs

- Total weight per foot: 60 lbs

Slab Dimensions: 20 feet by 10 feet.

Load Distribution:

- Uniform load calculation: Total pipe weight=60 lbs/ft×20 ft=1200 lbs\text{Total pipe weight} = 60 \, \text{lbs/ft} \times 20 \, \text{ft} = 1200 \, \text{lbs}Total pipe weight=60lbs/ft×20ft=1200lbs

- Distributed over slab area: Load per square foot=1200 lbs200 sq ft=6 lbs/sq ft\text{Load per square foot} = \frac{1200 \, \text{lbs}}{200 \, \text{sq ft}} = 6 \, \text{lbs/sq ft}Load per square foot=200sq ft1200lbs=6lbs/sq ft

Slab Thickness: Using ACI guidelines, a thickness of 6 inches is chosen for this load.

Reinforcement:

- Rebar size and spacing: #4 rebar, 12 inches on center, both ways.

- Placement: Positioned 2 inches from top and bottom surfaces of the slab.

Subgrade and Sub-base:

- Compacted subgrade.

- 6 inches of compacted crushed stone.

Load Combinations:

- Check for combined dead, live, and dynamic loads.

- Adjust slab design if additional loads (e.g., vehicle traffic) are expected.

Conclusion

Designing a grade slab to handle pipe loads involves careful consideration of the types of loads, material properties, and structural requirements. By following these steps and using appropriate design standards, you can ensure that the slab will adequately support the pipes and associated loads, providing a durable and reliable foundation

Considerations for Grade Slab Construction

- Load Requirements: The thickness and reinforcement of the slab should be designed based on the expected loads (dead loads, live loads, and dynamic loads).

- Soil Conditions: Conduct a soil investigation to determine the bearing capacity and settlement characteristics of the subgrade.

- Expansion Joints: Include expansion joints to accommodate thermal expansion and contraction, especially in large slabs.

- Drainage: Ensure proper site drainage to prevent water accumulation under the slab, which can lead to soil erosion and slab settlement.

- Insulation: In cold climates, consider adding insulation under the slab to prevent frost heave and improve energy efficiency.

Example of a Typical Grade Slab Design

- Subgrade: Compacted soil, leveled and free from organic materials.

- Sub-base: 6 inches of compacted crushed stone or gravel.

- DPM: 6-mil polyethylene sheet, properly sealed at overlaps.

- Reinforcement: #4 rebar spaced 12 inches on center, both ways.

- Concrete: 4 inches thick, M25 mix, placed in one continuous pour.

- Finishing: Smooth trowel finish with a broom texture for slip resistance.

- Curing: Cover with wet burlap for 7 days, keeping the surface moist.

By following these detailed steps and considerations, you can ensure a well-constructed grade slab that provides a strong, durable foundation for your building.