PURPOSE AND SCOPE

The scope of this document is to provide the calculations for the Analysis and Design of Steel Shelter.

The software used for structural analysis and design is STAAD Pro Connect Edition.

.A three-dimensional model of shelter structure is created in STAAD and all relevant loads are applied in accordance with ASCE 7-10 and member design is performed according to AISC-360-10.

In detailed design phase, appropriate design and detailing considerations as per AISC 341 shall be considered as necessary.

This document covers only sizing of primary steel members. The design of connections and sizing of secondary & tertiary steel members shall be performed in the detailed design phase.

REQUIRED REFERENCES

This section lists the practices, codes, standards, specifications, and publications that shall be used with this document. Unless otherwise specified herein, use the latest edition.

PROCESS INDUSTRY PRACTICES

PIP Description

PIP STC01015 Structural Design Criteria

INTERNATIONAL CODES

CODES Description

ASCE 7-10 Minimum Design Loads for Buildings and Other Structures

AISC 360-10 Specification for Structural Steel Buildings

AISC 341-10 Seismic Provisions for Structural Steel Buildings

REFERENCE LITERATURES

Reference Literature/ Design Guide Title

ASCE 41180 Wind Loads for Petrochemical and Other Industrial Facilities

ASCE 40262 Wind Loads and Anchor Bolt Design for Petrochemical Facilities

MATERIALS

All materials and structural steel components shall be in accordance with project specification “Design Specification for Steel Structures”.

|

Constant |

Value |

|

W-shapes, WT-shapes Yield strength, (Fy in MPa) |

ASTM A992/A992M |

|

345 |

|

|

S-shapes, Channels, Angles Yield strength, (Fy in MPa) |

ASTM A36/36M |

|

250 |

|

|

Elastic Modulus |

E = 210,000 MPa |

|

Density |

7850 kg/m3 |

|

Poisson’s Ratio |

ν = 0.3 |

|

Co-efficient of Thermal Expansion |

α = 12 x 10-6 m/m ℃ |

STRUCTURE DESCRIPTION

The Geometry of Off-gas Compressor Shelter is considered as per General Plot Plan Layout The dimension as below;

- Width of the structure is 15.00m;

- Length is 36.0m;

- Frame spacing is 6.0m;

- Eave height 15.00m

- Roof Slope is 1 in 10.

The shelter structure is enclosed with sheeting on all sides, except 3.0m opening above FGL. Shelter is considered to be supported on concrete pedestal of height 0.3 m from the ground.

Shelter consists of:

- Gantry girder supporting 8 MT rated capacity crane.

Moment resisting frames in transverse direction, braced framing in longitudinal direction. Column Base supports are fixed in transverse direction & pinned in longitudinal direction.

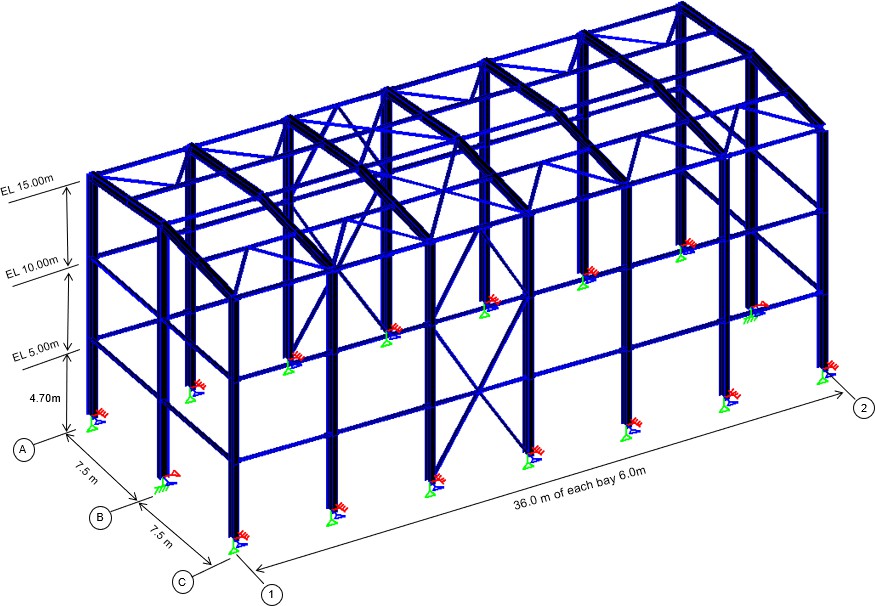

STAAD MODEL

Note:

Braces are considered as TRUSS members (pure Axial) in STAAD which is same as members with end moment releases.

Figure 4-2 Isometric View of Shelter with releases & support

NODE NUMBER

MEMBER PROPERTY

Figure Isometric View of Member Number

|

SL. No |

Member No |

Members |

|

1 |

R1 |

HE160A |

|

2 |

R2 |

HE160A |

|

3 |

R3 |

L120X120X12 SD |

|

4 |

R4 |

L90X90X10 SD |

|

5 |

R5 |

HE500A |

|

6 |

R6 |

HE600B |

|

7 |

R7 |

HE450A |

LOADS & LOAD COMBINATIONS

|

Load case No. |

Load case |

Loads |

|

1 |

DS |

DEAD LOAD (DS) |

|

2 |

L1 |

LIVE LOAD(L1) |

|

3 |

L2 |

CRANE IMPACT LOAD (L2) |

|

4 |

LR |

ROOF LIVE LOAD (LR) |

|

5 |

WX1(+) |

WIND LOAD (WX (+) CASE A Cpi = -0.18) |

|

6 |

WX2(+) |

WIND LOAD (WX (+) CASE B Cpi = 0.18) |

|

7 |

WX1(-) |

WIND LOAD (WX (-) CASE A Cpi = -0.18) |

|

8 |

WX2(-) |

WIND LOAD (WX (-) CASE B Cpi = 0.18) |

|

9 |

WZ1(+) |

WIND LOAD (WZ (+) CASE A Cpi = -0.18) |

|

10 |

WZ2(+) |

WIND LOAD (WZ (+) CASE B Cpi = 0.18) |

|

11 |

WZ1(-) |

WIND LOAD (WZ (-) CASE A Cpi = -0.18) |

|

12 |

WZ2(-) |

WIND LOAD (WZ (-) CASE B Cpi = 0.18) |

|

13 |

EX |

SEISMIC LOAD (EX) |

|

14 |

EZ |

SEISMIC LOAD (EZ) |

|

15 |

EY |

SEISMIC LOAD (EY) |

|

16 |

TS1 |

SUSTAINED THERMAL LOAD (TS MAX) |

|

17 |

TS2 |

SUSTAINED THERMAL LOAD (TS MIN) |

Table Primary Load case

DEAD LOAD (DS)

Structural self-weight of modelled steel members is automatically generated in STAAD.

Structural self-weight of all steel members is calculated with a unit weight of steel as 78.5kN/m3 multiplied by a contingency factor of 1.2 to account for connection details

Fire proofing to the structural members (column, beams & vertical bracing) is considered upto elevation 10 m. The 50mm thick concrete fireproofing is considered in accordance with “Passive Fire Protection Technical Specification. The fireproof weight is calculated automatically in STAAD.

|

Dead Load On Roof |

|||

|

Self-weight of roof/wall sheet (assumed) |

= |

6.00 |

kg/m2 |

|

= |

0.06 |

kN/m2 |

|

|

Self-weight of purlin and girts (UPN 200) |

= |

25.3 |

kg/m |

|

= |

0.25 |

kN/m |

|

|

Assuming purlins are located at every 1.0m spacing |

|||

|

Area load due to purlin |

= |

0.25 |

kN/m2 |

|

Total dead load for sheeting |

= |

0.25+0.06 |

|

|

= |

0.313 |

kN/m2 |

|

|

Considering 20% contingency for connections |

|||

|

Design dead load for sheeting |

= |

0.38 |

kN/m2 |

|

ROOF AREA |

||

|

Contributing span (m) |

Unit load (kN/m2) |

Sheet load including Purlin weight (kN/m) |

|

3 |

0.38 |

1.14 |

|

6 |

0.38 |

2.28 |

|

SIDE WALL |

||

|

Contributing span (m) |

Unit load (kN/m2) |

Side sheeting load including Side runner (kN/m) |

|

3 |

0.38 |

1.14 |

|

6 |

0.38 |

2.28 |

|

3.75 |

0.38 |

1.43 |

|

7.5 |

0.38 |

2.85 |

The Dead load of 2.5 kN/m shall be applied on longitudinal roof beams to account for roof ridge ventilation members.

Dead Load – Gantry Girder

Self weight of crane gantry girder

Self weight of supporting bracket beam

|

Gantry Girder |

Supporting Bracket Beam |

Total Force |

||||||

|

Contributing span (m) |

Unit load (kN/m) |

Selfweight of crane gantry girder (kN) |

Contributing span (m) |

Unit load (kN/m) |

Selfweight of Bracket Beam (kN) |

TOTAL Dead load, (kN) |

Lever Arm (m) |

Moment (kNm) |

|

3 |

1.18 |

3.54 |

1 |

1.25 |

1.25 |

4.79 |

1 |

4.79 |

|

6 |

1.18 |

7.08 |

1 |

1.25 |

1.25 |

8.33 |

1 |

8.33 |

Crane Dead Load (CD)

Crane load is considered 8T lifting capacity (Assumed).

For the overall structural design, the critical crane load calculated is applied on all the frames. The Crane Loads are applied at EL (+)12.00m.

Design Load calculation is as follows.

Rated load capacity of crane W = 8000 kg = 80 kN

Span of crane = 15.00 m

Weight of crane bridge (INCLUDED OTHER WEIGHTS) Wc

= 4000 kg = 40 kN

Weight of hoist and trolley Wt = 800 kg = 8 kN

No of wheel on each side = 2

No’s

Wheel base = 3.15 m

Distance of the hook from grid-1 = 1 m

Distance of the hook from grid-3

Primary Load cases due to Crane operation:

= 1 m

Dead (CD) = vertical dead load of the crane + trolley weight

1) Wheel load due to crane bridge

(Crane bridge load / 2) / No. of Wheel on one side = ( 40 / 2 ) / 2

= 10 kN

2) Wheel load due to hoist and trolley 8 T

- When hook is near grid –A

Wheel load on grid -A = 3.73 kN = ( 8 x 14 / 15 ) / 2

Wheel load on grid -C = 0.27 kN = ( 8 x 1 / 15 ) / 2

|

Wheel Load |

Bridge Load kN |

Trolley Load kN |

Dead (CD) = Bridge Load + Trolley Load kN |

|

Wheel load along grid A |

10.00 |

3.73 |

13.73 |

|

Wheel load along grid C |

10.00 |

0.27 |

10.27 |

Figure Crane-Dead Load Max Staad reaction on Grid A column support

- Maximum Wheel load = 24.540 kN (applied in staad for all gantry support columns)

- Moment due to gantry supporting beam = 1m; 24.54 x 1m =24.540 kNm

Figure Crane-Dead Load Max Staad reaction on Grid C column support

- Maximum Wheel load = 18.355 kN (applied in staad for all gantry support columns)

- Moment due to gantry supporting beam = 1m; 18.355 x 1m = 18.355 kNm

LIVE LOAD (L1)

The Walk way of width 1.0m is assumed for crane accessibility at EL (+)12.00m. The live Load is considered as 2.87kN/m² (Section 4.1.3 of PIP STC01015).

|

Platform LL |

= |

2.87 |

kN/m2 |

|

|

Width |

= |

1 |

m |

|

|

Contributing span (m) |

Unit Load (kN/m2) |

Live Load on Platform (kN) |

||

|

3 |

2.87 |

8.61 |

||

|

6 |

2.87 |

17.22 |

||

CRANE IMPACT LOAD (L2)

CRANE OPERATING (CO)

Wheel load due to Rated load Capacity = 80 Kn

Grid A Grid C

When hook is near grid –A

Wheel load on grid -A = ( 80 x 14 / 15 ) / 2 = 37.33 kN

Wheel load on grid -C = ( 80 x 1 / 15 ) / 2 = 2.67 kN

|

Wheel Load |

Crane Operating (CO) kN |

|

Wheel load along grid A |

37.33 |

|

Wheel load along grid C |

2.67 |

Crane-Operating Load Max reaction on Grid A column support

- Maximum wheel load = 66.719 kN (applied in staad for all gantry support columns)

- Moment due to gantry supporting beam = 1m; 66.719 x 1m =66.719 kNm

2.67 kN

2.67 kN

Crane-Operating Load Max reaction on Grid C column support

- Maximum wheel load = 4.772 kN (applied in staad for all gantry support columns)

- Moment due to gantry supporting beam = 1m; 4.772 x 1m =4.772 kNm

Structural Crane Operating Load (CO)

CRANE TRANSVERSE (CT)

As per ASCE 7-10, refer 4.9

|

Transverse (CT) |

= |

side thrust (transversal Impact load) |

|

= |

20% of the rated load capacity of the crane and the weight of the hoist and trolley (as per cl 4.9.4 of ASCE 7-10) |

|

Wheel Load |

Trolley Load |

Crane Operating (CO) |

Crane Transverse (CT) = 0.20*(trolley load+CO) kN |

|

Wheel load along grid A |

3.73 |

37.33 |

8.21 |

|

Wheel load along grid C |

0.27 |

2.67 |

0.59 |

Crane-Side Thrust Load Max reaction on Grid A column support

Crane-Side Thrust Load Max reaction on Grid A column support

Maximum wheel load = 14.674 kN (applied in staad laterally for all gantry support columns)

Maximum wheel load = 14.674 kN (applied in staad laterally for all gantry support columns)

Crane-Side Thrust Load Max reaction on Grid C column support

Maximum wheel load = 1.055 kN (applied in staad laterally for all gantry support columns)

Figure 5-10 Structural Crane Side Thrust Load (CT)

CRANE LONGITUDINAL (CL)

As per ASCE 7-10, refer 4.9

|

Longitudinal (CL) |

= |

longitudinal traction (longitudinal Impact load) |

|

= |

10% of the maximum wheel load (= 0.1*(CD+CO)) (as per cl 4.9.5 of ASCE 7-10) |

|

Wheel Load |

Crane Dead (CD) |

Crane Operating (CO) |

Crane Longitudinal (CL) = 0.10*(CD+CO) *No. of wheels on each side |

|

Wheel load along grid A |

13.73 |

37.33 |

5.1 |

|

Wheel load along grid C |

10.27 |

2.67 |

1.29 |

Maximum reaction on Grid A = 10.21 kN (applied in staad longitudinally for critical support columns)

Maximum reaction on Grid C = 2.59 kN (applied in staad longitudinally for critical support columns)

Figure 5-11 Structural Crane Longitudinal Load (CL)

CRANE IMPACT (CI)

As per ASCE 7-10, refer 4.9

|

Impact (CI) |

= |

vertical impact |

|

= |

25% of the maximum vertical wheel load (= 0.25*(CD+CO)) (as per cl 4.9.3 of ASCE 7-10) |

|

Wheel Load |

Crane Dead (CD) |

Crane Operating (CO) |

Crane Longitudinal (CL) = 0.20*(CD+CO) |

|

Wheel load along grid-A |

13.73 |

37.33 |

12.77 |

|

Wheel load along grid-C |

10.26 |

2.67 |

3.23 |

Crane-Impact Load Max reaction on Grid 1 column support

- Maximum wheel load = 5.773 kN (applied in staad for all gantry support columns)

- Moment due to gantry supporting beam = 1m; 5.773 x 1m = 5.773 kNm

Figure 5-14 Structural Crane Impact Load (CI)

ROOF LIVE LOAD (LR)

Live load on Roof is considered as 0.96 kN/m2 (Refer Table 4.1, ASCE 7-10). Load is applied as UDL on the supporting main beams. The roof live load is reduced as per Section 4.8.2 of ASCE 7-10.

![]()

|

AT – Tributary area |

= 6*15 = 90 m2 |

|

|

F – 0.12 * slope (in %) |

= 0.12*10 = 1.2 |

|

|

R1 = 0.6 |

(AT > 55.74 m2) |

|

|

R2 = 1 |

(F < 4) |

Lr = 0.96*0.6 = 0.58 kN/m2

|

Contributing span (m) |

Unit Load (kN/m2) |

Live Load on Roof (kN/m) |

|

3 |

0.58 |

1.74 |

|

6 |

0.58 |

3.48 |

WIND LOAD (WLX & WLZ)

Wind Parameters:

Structure Risk Category = III

(3sec-gust) = 85.70 m/s

(Return Period – 1700 years is considered for risk category III structures)

F, applied wind force = qz G Cf Af (Eq. 29.5-1), ASCE 7-10 qz – Velocity Pressure at height z above Ground.

G – Gust effect factor

Cf – Net force coefficient

Af – Projected area normal to wind

Velocity Pressure qz:

qz, (N/m2) = 0.613 Kz Kzt Kd V2 (Eq. 27.3-1), ASCE 7 -10

Kz, Velocity pressure exposure coefficient Kzt, Topographic factor

Kd, Wind directionality factor

V, Basic wind speed (3 sec – Gust) m/s Kz, Velocity pressure exposure coefficient

|

Exposure |

||||

|

m |

ft |

C |

D |

D normalized to 1.0 at 33 ft |

|

4.57 |

15 |

0.85 |

1.03 |

0.87 |

|

6.10 |

20 |

0.9 |

1.08 |

0.92 |

|

7.62 |

25 |

0.94 |

1.12 |

0.95 |

|

9.14 |

30 |

0.98 |

1.16 |

0.98 |

|

12.19 |

40 |

1.04 |

1.22 |

1.03 |

|

15.24 |

50 |

1.09 |

1.27 |

1.08 |

|

18.29 |

60 |

1.13 |

1.31 |

1.11 |

|

21.34 |

70 |

1.17 |

1.34 |

1.14 |

|

24.38 |

80 |

1.21 |

1.38 |

1.17 |

Exposure Factor = D

Provided wind speed is representative of the Exposure Category-D, then there is no additional adjustment of pressure for Exposure Category

Kzt, Topographic factor

H, Height of hill or escarpment = 27 m (Grading level)

Lh, Distance upwind of crest at H/2 = 50 m (shore to escarpment = 100m)

x, Distance from crest to building site = 100 m (escarpment to bldg = 100m)

z, Ht above ground surface at bldg site = 42.75 m 27+ ht of shelter

Considering 2-D escarpments

μ, Horizontal attenuation factor = 4 Figure 26.8-1 (ASCE 7-10) – down wind

γ, Height attenuation factor = 2.5 Figure 26.8-1 (ASCE 7-10)

k1, (k1/(H/Lh) = 0.95

= 0.513

k2, = 0.5

k3, = 0.118

Kzt, . = 1.06

Kd, Wind directionality factor = 0.85 Table 26.6-1, ASCE 7-10

G – Gust effect factor = 0.85 26.9.1, ASCE 7-10

|

Level |

Height above ground “m” |

Kz |

Kzt |

Kd |

qp(z) (kN/m²) |

G * qp(z) (kN/m²) |

|

|

Level-1 |

0.00 – |

5.00 |

0.884 |

1.060 |

0.850 |

3.587 |

3.05 |

|

Level-2 |

5.00 – |

10.00 |

0.994 |

1.060 |

0.850 |

4.033 |

3.43 |

|

Level-3 |

10.00 – |

15.00 |

1.076 |

1.060 |

0.850 |

4.366 |

3.71 |

|

Level-4 |

15.00 – |

20.00 |

1.127 |

1.060 |

0.850 |

4.572 |

3.89 |

|

Level-5 |

20.00 – |

25.00 |

1.174 |

1.060 |

0.850 |

4.763 |

4.05 |

|

Level-6 |

25.00 – |

30.00 |

1.207 |

1.060 |

0.850 |

4.896 |

4.16 |

|

Level-7 |

30.00 – |

40.00 |

1.272 |

1.060 |

0.850 |

5.162 |

4.39 |

|

Level-8 |

40.00 – |

50.00 |

1.316 |

1.060 |

0.850 |

5.339 |

4.54 |

Table 5-3 : Wind pressure for height z

Cf – Net force coefficient

Ref: Sec. 4.1, ASCE-Report – Wind Loads and Anchor Bolt Design for Petrochemical Facilities For Structural member = = 1.8

Force on Pipe: F = qzxGxCfxAf

Wind Force along X direction: (No sheeting up to 3m)

|

z, (m) |

Member Property |

Member depth/ width (m) |

Insulation width |

wind expose depth / width |

F in X Direction (kN/m) (Per frame) |

|

3.00 |

HE600B |

0.600 |

0.05 |

0.700 |

3.84 |

|

3.00 |

HE550A |

0.300 |

0.05 |

0.400 |

2.2 |

|

3.00 |

L120X120X12 |

0.120 |

0.05 |

0.220 |

1.26 |

Wind Force along Z direction:

|

z, (m) |

Member Property |

Member depth/ width (m) |

Insulation width |

wind expose Depth / width |

F in Z Direction (kN/m) (Per frame) |

|

3.00 |

HE600B |

0.300 |

0.05 |

0.40 |

2.2 |

|

3.00 |

HE550A |

0.540 |

0.05 |

0.64 |

3.51 |

|

3.00 |

L120X120X12 |

0.120 |

0.05 |

0.220 |

1.26 |

Wind Load on Structure, Roof and Side Walls along X (+) direction-Load Case A

Wind Load on Structure, Roof and Side Walls along X (+) direction-Load Case B

Wind load on WX(-) calculations are same as wind load on WX(+), only direction change has been applied in staad.

WIND LOAD (WX(-) CASE A Cpi = -0.18)

Wind Load on Structure, Roof and Side Walls along X (-) direction-Load Case A

WIND LOAD (WX(-) CASE B Cpi = 0.18)

Wind Load on Structure, Roof and Side Walls along X (-) direction-Load Case B

Wind Load on Structure, Roof and Side Walls along Z (+) direction-Load Case A

Wind Load on Structure, Roof and Side Walls along Z (+) direction-Load Case B

Wind load on WZ(-) calculations are same as wind load on WZ(+), only direction change has been applied in staad.

WIND LOAD (WZ(-) CASE A Cpi = -0.18)

Wind Load on Structure, Roof and Side Walls along Z (-) direction-Load Case A

WIND LOAD (WZ(-) CASE B Cpi = 0.18)

Wind Load on Structure, Roof and Side Walls along Z (-) direction-Load Case B

SEISMIC LOAD (EX/EZ/EY)

For Time Period greater than Long Period Transition Period TL

T> TL Cs =(SD1*TL)/T2*(R/I) Eq.12.8-4/ASCE-7

|

Cs, Seismic response coefficient |

= |

(SD1*TL) |

|||

|

T2*(R/I) |

|||||

|

Cs along frame in X-Dir |

= |

4.0280 |

|||

|

Cs along frame in Z-Dir Minimum Cs, Seismic response coefficient |

= = |

0.7840 0.044SDS*I > |

0.01 |

Eq.12.8-5/ASCE-7 |

|

|

= |

0.0165 |

> |

0.01 |

||

|

Cs, along frame in X dir |

= |

0.1280 |

> |

0.1160 |

|

|

Cs, along frame in Z dir |

= |

0.0550 |

< |

0.1080 |

|

|

Hence actual value of Cs |

|||||

|

Cs, along frame in X dir |

= |

0.1160 |

|||

|

Cs, along frame in Z dir |

= |

0.0550 |

|||

Operating condition

The Seismic weight, includes the weight of structure, equipment loads and operating loads.

|

Redundancy Factor ρ |

= |

1 |

12.3.4.1/ASCE-7 |

|

|

Total weight (D) |

= |

2152 |

kN (from Staad) |

|

|

Base shear along xdir |

(2152×0.116) |

= |

249.63 |

kN (CsW) |

|

Base shear along Zdir |

(2152×0.055) |

= |

118.36 |

kN (CsW) |

CALCULATION OF BASE SHEAR

The Seismic weight W, includes the weight of structure,equipment loads and operating load

|

W, Total weight |

= |

2152 |

kN |

|

|

For X V,Base shear along frame X Dir |

= |

249.63 |

kN |

|

|

Enhanced Base shear including ρ & Ω0 |

= |

249.63 |

kN |

|

|

Comparison with STAAD |

||||

|

V,Base shear along frame X Dir |

= |

219.2 |

kN |

|

|

For Z V,Base shear along frame Z Dir |

= |

118.36 |

kN |

|

|

Enhanced Base shear including ρ & Ω0 |

= |

118.36 |

kN |

|

|

Comparison with STAAD |

||||

|

V,Base shear along frame Z Dir |

= |

107 |

kN |

|

|

Next Iteration 0.85 V, Base shear along Frame in X dir |

= |

212.19 |

kN |

12.9.4/ ASCE 7 |

= 0.968 <1 Shear enhancement Not required

|

Next Iteration |

||||

|

0.85 V, Base shear along Frame in Z dir |

= |

100.61 |

kN |

12.9.4/ ASCE 7 |

= 0.940 =<1 Shear enhancement Not required

|

Vertical load effect on structure |

||||

|

Ev, Vertical earthquake load effect Vertical load effect on structure |

= = |

0.2*SDS*D 129.12 |

kN |

Eq.12.4-4/ASCE-7 |

Seismic load in X/Z/Y – Direction

THERMAL LOAD (Ts1 & Ts2)

Temperature load is considered as per Section 6.5 of “Basic Engineering Design Data (BEDD) Onshore

The thermal load for the structure is considered for the maximum temperature variation of +42°C and minimum temperature variation of 6°C from the ambient temperature.

Maximum Temperature : 42°C

Minimum Temperature : 6°C Mean Ambient Temperature : 26°C

TS1 max = 42 – 26 = +16 °C TS2 min = 6 – 26 = – 20 °C

SERVICIABILITY LOAD COMBINATION

|

S.no |

Buildings and Open Frame Structures Specific Load Combination |

Description |

|

1 |

Ds + Ts |

Dead Weight + Sustained Thermal (Sustained Load Case for Deflection or Settlement) |

|

2 |

Ds + Ts + L |

Dead Weight + Sustained Thermal + Live |

|

3 |

N/A |

|

|

4 |

Ds + Ts + 0.75 L + 0.75 Lr |

Dead Weight + Sustained Thermal + Live + Roof Live |

|

5 |

Ds + Ts + 0.6 W |

Dead Weight + Sustained Thermal + Wind |

|

Ds + Ts + E* |

Dead Weight + Sustained Thermal + Earthquake |

|

|

6a |

Ds + Ts + 0.75 L + 0.75 (0.6 W) + 0.75 Lr |

Dead Weight + Sustained Thermal + Live + Wind + Roof Live |

|

6b |

Ds + Do + Ts + 0.75 L + 0.75 E* |

Dead Weight + Sustained Thermal + Live + Earthquake |

|

7 |

0.6 (Ds) + Ts + 0.6 W |

Dead Weight + Sustained Thermal + Wind (Wind Uplift Case) |

|

8 |

0.6 (Ds) + Ts + E* |

Dead Weight + Sustained Thermal + Earthquake (Earthquake Uplift Case) |

*Deflection shall be computed using the strength level seismic forces as specified in Section 12.8 of ASCE 7-10 without reduction for allowable stress design.

|

Load |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

|

Comb |

DS |

L1 |

L2 |

LR |

WX1 (+) |

WX2 (+) |

WX1 (-) |

WX2 (-) |

WZ1 (+) |

WZ2 (+) |

WZ1 (-) |

WZ2 (-) |

EX |

EZ |

EY |

TS 1 |

TS2 |

|

101 |

1 |

1 |

|||||||||||||||

|

102 |

1 |

1 |

|||||||||||||||

|

103 |

1 |

1 |

1 |

1 |

|||||||||||||

|

104 |

1 |

1 |

1 |

1 |

|||||||||||||

|

105 |

1 |

1 |

1 |

||||||||||||||

|

106 |

1 |

1 |

1 |

||||||||||||||

|

107 |

1 |

0.75 |

0.75 |

0.75 |

1 |

||||||||||||

|

108 |

1 |

0.75 |

0.75 |

0.75 |

1 |

||||||||||||

|

109 |

1 |

0.6 |

1 |

||||||||||||||

|

110 |

1 |

0.6 |

1 |

||||||||||||||

|

111 |

1 |

0.6 |

1 |

||||||||||||||

|

112 |

1 |

0.6 |

1 |

||||||||||||||

|

113 |

1 |

0.6 |

1 |

||||||||||||||

|

114 |

1 |

0.6 |

1 |

||||||||||||||

|

115 |

1 |

0.6 |

1 |

||||||||||||||

|

116 |

1 |

0.6 |

1 |

||||||||||||||

|

117 |

1 |

0.6 |

1 |

||||||||||||||

|

118 |

1 |

0.6 |

1 |

||||||||||||||

|

119 |

1 |

0.6 |

1 |

||||||||||||||

|

120 |

1 |

0.6 |

1 |

||||||||||||||

|

121 |

1 |

0.6 |

1 |

||||||||||||||

|

122 |

1 |

0.6 |

1 |

||||||||||||||

|

123 |

1 |

0.6 |

1 |

||||||||||||||

|

124 |

1 |

0.6 |

1 |

||||||||||||||

|

125 |

1 |

1 |

0.3 |

1 |

1 |

||||||||||||

|

126 |

1 |

0.3 |

1 |

1 |

1 |

||||||||||||

|

127 |

1 |

-1 |

-0.3 |

1 |

1 |

||||||||||||

|

128 |

1 |

-0.3 |

-1 |

1 |

1 |

||||||||||||

|

129 |

1 |

1 |

0.3 |

1 |

1 |

||||||||||||

|

130 |

1 |

0.3 |

1 |

1 |

1 |

||||||||||||

|

131 |

1 |

-1 |

-0.3 |

1 |

1 |

||||||||||||

|

132 |

1 |

-0.3 |

-1 |

1 |

1 |

||||||||||||

|

133 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

134 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

135 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

136 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

137 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

138 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

139 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

140 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

141 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

142 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

143 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

144 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

145 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

146 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

147 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

148 |

1 |

0.75 |

0.75 |

0.45 |

1 |

||||||||||||

|

149 |

1 |

0.75 |

0.75 |

0.23 |

0.75 |

1 |

|||||||||||

|

150 |

1 |

0.75 |

0.23 |

0.75 |

0.75 |

1 |

|||||||||||

|

151 |

1 |

0.75 |

-0.75 |

-0.23 |

0.75 |

1 |

|||||||||||

|

152 |

1 |

0.75 |

-0.23 |

-0.75 |

0.75 |

1 |

|||||||||||

|

153 |

1 |

0.75 |

0.75 |

0.23 |

0.75 |

1 |

|||||||||||

|

154 |

1 |

0.75 |

0.23 |

0.75 |

0.75 |

1 |

|||||||||||

|

155 |

1 |

0.75 |

-0.75 |

-0.23 |

0.75 |

1 |

|||||||||||

|

156 |

1 |

0.75 |

-0.23 |

-0.75 |

0.75 |

1 |

|||||||||||

|

157 |

0.6 |

0.6 |

1 |

||||||||||||||

|

158 |

0.6 |

0.6 |

1 |

||||||||||||||

|

159 |

0.6 |

0.6 |

1 |

||||||||||||||

|

160 |

0.6 |

0.6 |

1 |

||||||||||||||

|

161 |

0.6 |

0.6 |

1 |

||||||||||||||

|

162 |

0.6 |

0.6 |

1 |

||||||||||||||

|

163 |

0.6 |

0.6 |

1 |

||||||||||||||

|

164 |

0.6 |

0.6 |

1 |

||||||||||||||

|

165 |

0.6 |

0.6 |

1 |

||||||||||||||

|

166 |

0.6 |

0.6 |

1 |

||||||||||||||

|

167 |

0.6 |

0.6 |

1 |

||||||||||||||

|

168 |

0.6 |

0.6 |

1 |

||||||||||||||

|

169 |

0.6 |

0.6 |

1 |

||||||||||||||

|

170 |

0.6 |

0.6 |

1 |

||||||||||||||

|

171 |

0.6 |

0.6 |

1 |

||||||||||||||

|

172 |

0.6 |

0.6 |

1 |

||||||||||||||

|

173 |

0.6 |

1 |

0.3 |

1 |

1 |

||||||||||||

|

174 |

0.6 |

0.3 |

1 |

1 |

1 |

||||||||||||

|

175 |

0.6 |

-1 |

-0.3 |

1 |

1 |

||||||||||||

|

176 |

0.6 |

-0.3 |

-1 |

1 |

1 |

||||||||||||

|

177 |

0.6 |

1 |

0.3 |

1 |

1 |

||||||||||||

|

178 |

0.6 |

0.3 |

1 |

1 |

1 |

||||||||||||

|

179 |

0.6 |

-1 |

-0.3 |

1 |

1 |

||||||||||||

|

180 |

0.6 |

-0.3 |

-1 |

1 |

1 |

STRENGTH LOAD COMBINATION

|

S.no |

Buildings and Open Frame Structures Specific Load Combination |

Description |

|

1 |

1.4 Ds + 1.2 Ts |

Dead Weight + Sustained Thermal |

|

2 |

1.2 Ds + 1.2 Ts +1.6 L + 0.5 Lr |

Dead Weight + Sustained Thermal + Live + Roof Live |

|

3 |

1.2 Ds + 1.2 Ts + 1.6 Lr + L |

Dead Weight + Sustained Thermal + Roof Live + Live |

|

1.2 Ds + 1.2 Ts + 1.6 Lr + 0.5 W |

Dead Weight + Sustained Thermal + Roof Live + Wind |

|

|

4 |

1.2 Ds + 1.2 Ts + 1.0 W + L + 0.5 Lr |

Dead Weight + Sustained Thermal + Wind + Live + Roof Live |

|

5 |

1.2 Ds + 1.2 Ts + 1.0 E + 0.5 L |

Dead Weight + Sustained Thermal + Earthquake + Live |

|

6 |

0.9 Ds + 1.2 Ts + 1.0 W |

Dead Weight + Sustained Thermal + Wind (Wind Uplift Case) |

|

7 |

0.9 Ds + 1.2 Ts + 1.0 E |

Dead Weight + Sustained Thermal + Earthquake (Earthquake Uplift Case) |

|

Load |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

|

Comb |

DS |

L1 |

L2 |

LR |

WX1 (+) |

WX2 (+) |

WX1 (-) |

WX2 (-) |

WZ1 (+) |

WZ2 (+) |

WZ1 (-) |

WZ2 (-) |

EX |

EZ |

EY |

TS1 |

TS2 |

|

201 |

1.4 |

1.2 |

|||||||||||||||

|

202 |

1.4 |

1.2 |

|||||||||||||||

|

203 |

1.2 |

1.6 |

1.6 |

0.5 |

1.2 |

||||||||||||

|

204 |

1.2 |

1.6 |

1.6 |

0.5 |

1.2 |

||||||||||||

|

205 |

1.2 |

1 |

1 |

1.6 |

1.2 |

||||||||||||

|

206 |

1.2 |

1 |

1 |

1.6 |

1.2 |

||||||||||||

|

207 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

208 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

209 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

210 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

211 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

212 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

213 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

214 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

215 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

216 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

217 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

218 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

219 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

220 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

221 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

222 |

1.2 |

1.6 |

0.5 |

1.2 |

|||||||||||||

|

223 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

224 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

225 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

226 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

227 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

228 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

229 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

230 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

231 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

232 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

233 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

234 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

235 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

236 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

237 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

238 |

1.2 |

1 |

0.5 |

1 |

1.2 |

||||||||||||

|

239 |

1.2 |

1 |

1 |

0.3 |

1 |

1.2 |

|||||||||||

|

240 |

1.2 |

1 |

0.3 |

1 |

1 |

1.2 |

|||||||||||

|

241 |

1.2 |

1 |

-1 |

-0.3 |

1 |

1.2 |

|||||||||||

|

242 |

1.2 |

1 |

-0.3 |

-1 |

1 |

1.2 |

|||||||||||

|

243 |

1.2 |

1 |

1 |

0.3 |

1 |

1.2 |

|||||||||||

|

244 |

1.2 |

1 |

0.3 |

1 |

1 |

1.2 |

|||||||||||

|

245 |

1.2 |

1 |

-1 |

-0.3 |

1 |

1.2 |

|||||||||||

|

246 |

1.2 |

1 |

-0.3 |

-1 |

1 |

1.2 |

|||||||||||

|

247 |

0.9 |

1 |

1.2 |

||||||||||||||

|

248 |

0.9 |

1 |

1.2 |

||||||||||||||

|

249 |

0.9 |

1 |

1.2 |

||||||||||||||

|

250 |

0.9 |

1 |

1.2 |

||||||||||||||

|

251 |

0.9 |

1 |

1.2 |

||||||||||||||

|

252 |

0.9 |

1 |

1.2 |

||||||||||||||

|

253 |

0.9 |

1 |

1.2 |

||||||||||||||

|

254 |

0.9 |

1 |

1.2 |

||||||||||||||

|

255 |

0.9 |

1 |

1.2 |

||||||||||||||

|

256 |

0.9 |

1 |

1.2 |

||||||||||||||

|

257 |

0.9 |

1 |

1.2 |

||||||||||||||

|

258 |

0.9 |

1 |

1.2 |

||||||||||||||

|

259 |

0.9 |

1 |

1.2 |

||||||||||||||

|

260 |

0.9 |

1 |

1.2 |

||||||||||||||

|

261 |

0.9 |

1 |

1.2 |

||||||||||||||

|

262 |

0.9 |

1 |

1.2 |

||||||||||||||

|

263 |

0.9 |

1 |

0.3 |

1 |

1.2 |

||||||||||||

|

264 |

0.9 |

0.3 |

1 |

1 |

1.2 |

||||||||||||

|

265 |

0.9 |

-1 |

-0.3 |

1 |

1.2 |

||||||||||||

|

266 |

0.9 |

-0.3 |

-1 |

1 |

1.2 |

||||||||||||

|

267 |

0.9 |

1 |

0.3 |

1 |

1.2 |

||||||||||||

|

268 |

0.9 |

0.3 |

1 |

1 |

1.2 |

||||||||||||

|

269 |

0.9 |

-1 |

-0.3 |

1 |

1.2 |

||||||||||||

|

270 |

0.9 |

-0.3 |

-1 |

1 |

1.2 |

UNITY CHECK

Design of the structure is performed using STAAD software and ensured member design adequacy. The unity ratios of the members are presented below.

|

Strength Case: |

|||||

|

Member Description |

Beam No. |

Member Property |

Load Combination |

UC Ratio |

Allowable Ratio |

|

Column |

7 |

HE600B* |

261 |

0.65 |

0.9 |

|

Cable End Column |

200 |

HE500A* |

233 |

0.68 |

0.9 |

|

Rafter Beam |

43 |

HE450A* |

262 |

0.65 |

0.9 |

|

Longitudinal Tie Beam |

31 |

HE160A |

231 |

0.59 |

0.9 |

|

Vertical Bracing |

65 |

L120X120X12 SD |

225 |

0.81 |

0.81 |

|

Horizontal Bracing |

93 |

L90X90X10 SD |

223 |

0.39 |

0.80 |

*Member Size are governed by Deflection criteria refer. Section 6.2.1

BASE REACTION

|

L/C |

Horizontal |

Vertical |

Horizontal |

Moment |

||

|

Fx kN |

Fy kN |

Fz kN |

Mx kN-m |

My kN-m |

Mz kN-m |

|

|

1 DEAD LOAD (DS) |

0 |

2269 |

0 |

20 |

0 |

0 |

|

2 LIVE LOAD(L1) |

0 |

207 |

0 |

0 |

0 |

0 |

|

3 CRANE IMPACT LOAD (L2) |

13 |

700 |

110 |

1196 |

0 |

1 |

|

4 ROOF LIVE LOAD (LR) |

0 |

315 |

0 |

0 |

0 |

0 |

|

5 WIND LOAD (WX(+) CASE A CPI = -0.18) |

-869 |

-1395 |

0 |

0 |

0 |

814 |

|

6 WIND LOAD (WX(+) CASE B CPI = 0.18) |

-869 |

-2258 |

0 |

0 |

0 |

815 |

|

7 WIND LOAD (WX(-) CASE A CPI = -0.18) |

869 |

-1395 |

0 |

0 |

0 |

-817 |

|

8 WIND LOAD (WX(-) CASE B CPI = 0.18) |

869 |

-2258 |

0 |

0 |

0 |

-815 |

|

9 WIND LOAD (WZ(+) CASE A CPI = -0.18) |

0 |

1601 |

-1770 |

-11093 |

0 |

1 |

|

10 WIND LOAD (WZ(+) CASE B CPI = 0.18) |

0 |

2458 |

-1770 |

-11034 |

0 |

2 |

|

11 WIND LOAD (WZ(-) CASE A CPI = -0.18) |

0 |

1601 |

1770 |

11093 |

0 |

1 |

|

12 WIND LOAD (WZ(-) CASE B CPI = 0.18) |

0 |

2458 |

1770 |

11034 |

0 |

2 |

|

13 SEISMIC LOAD (EX) |

224 |

913 |

7 |

33 |

0 |

40 |

|

14 SEISMIC LOAD (EZ) |

5 |

67 |

113 |

948 |

0 |

0 |

|

15 SEISMIC LOAD (EY) |

0 |

124 |

0 |

0 |

0 |

0 |

|

16 SUSTAINED THERMAL LOAD (TS MAX) |

0 |

0 |

0 |

0 |

0 |

3 |

|

17 SUSTAINED THERMAL LOAD (TS MIN) |

0 |

0 |

0 |

0 |

0 |

-3 |

- 3D HOUSE DESIGN (34)

- Civil and Structural Design Calculations (76)

- Commercial Plans (9)

- East Facing House Plans (14)

- Engineering Concepts – Civil & Structural (224)

- Excel Spreadsheets (37)

- Free Downloads (49)

- House Plans (57)

- Industrial standards (91)

- North Facing House Plans (15)

- South Facing House Plans (15)

- West Facing House Plans (9)