Box culvert design according to IRC 6 (Standard Specifications and Code of Practice for Road Bridges, Section II) involves several considerations for structural strength, stability, and durability. Here are the main design bases to consider:

1. Load Considerations

- Dead Load: Weight of the box culvert, including the self-weight of the concrete, parapets, and other permanent structural components.

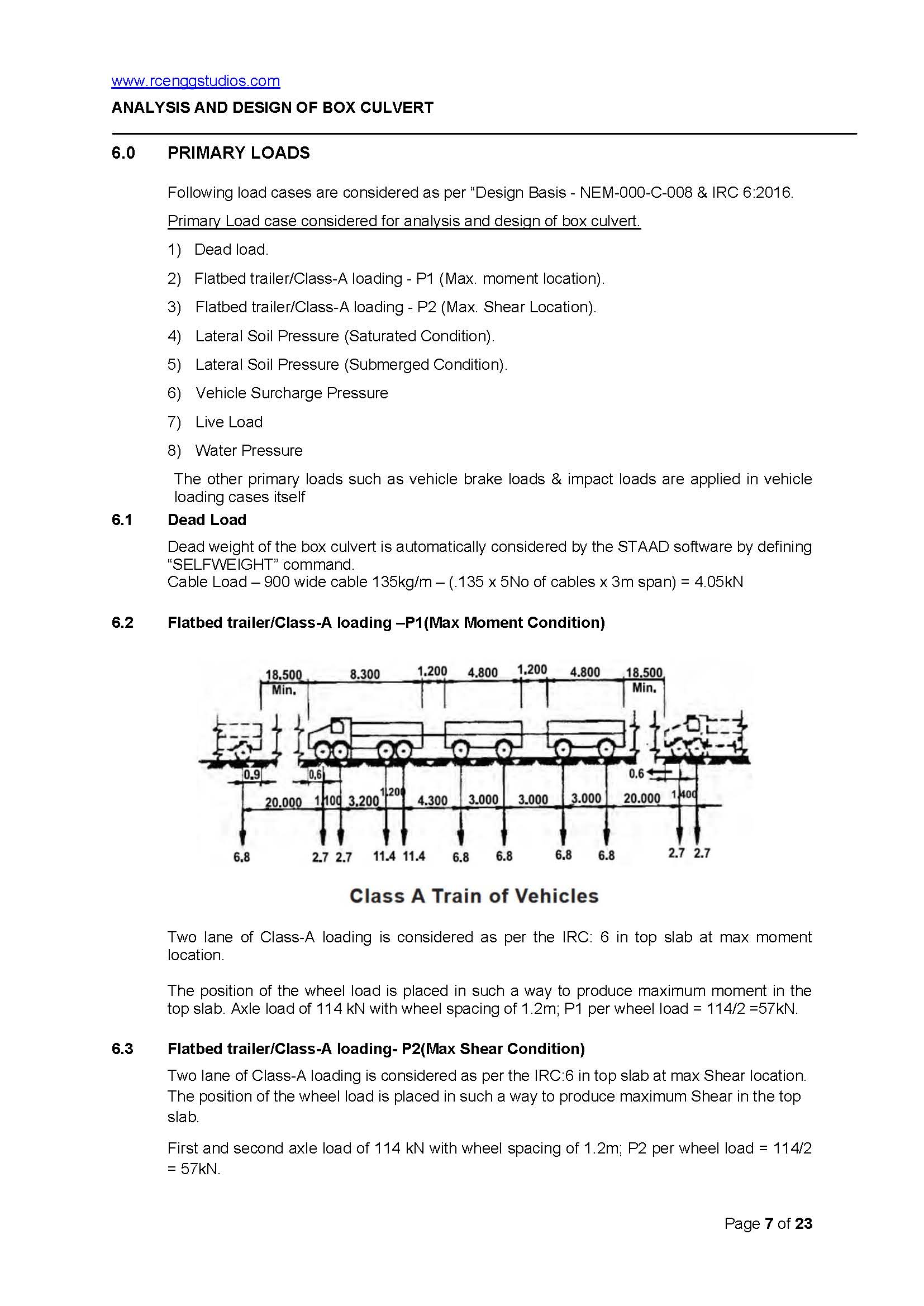

- Live Load: Vehicular load as per IRC 6, generally adopting IRC Class A, AA, or 70R loading, depending on the culvert’s location and importance.

- Impact Load: Apply an impact factor as per IRC 6 if vehicles can travel directly over the culvert, based on the design speed and load class.

- Surcharge Load: Lateral earth pressure due to embankment or backfill material on top of the box culvert.

- Water Load: Hydrostatic pressure exerted by water on the culvert, considering maximum water levels and pressure distributions.

- Earth Pressure: Lateral and vertical earth pressure, depending on soil type, compaction, and depth of the cover.

2. Design Parameters

- Effective Span and Depth: Determine based on the roadway width, hydraulic needs, and site conditions.

- Material Strengths:

- Use minimum M25 grade concrete and Fe 500 steel as specified by IRC standards for durability.

- Reinforcement Detailing: Reinforcement should comply with IRC standards for ductility and resilience against loading.

- Clear Cover: Provide a minimum cover as specified by IRC to protect reinforcement from environmental exposure.

3. Hydraulic Design

- Calculate the hydraulic capacity based on IRC SP 13 to ensure the culvert can handle expected water flows.

- Check for scouring and erosion potential and design to mitigate these effects.

4. Structural Design Checks

- Bending Moment and Shear Force: Calculate moments and shear at various sections (e.g., midspan, supports) using the loads and support conditions. Ensure compliance with bending and shear capacities as per IS 456 and IRC standards.

- Serviceability Checks: Check for deflection, cracking, and durability. IRC specifies crack width limits and deflection limits based on service life requirements.

5. Other Considerations

- Thermal Effects: Design for temperature gradients in areas with significant seasonal temperature variations.

- Durability and Service Life: Select materials and design thicknesses to ensure a long service life with minimal maintenance.

- Construction Joints: Place construction joints according to IRC specifications to accommodate differential settlement and thermal movements.

6. Load Combinations

- Apply various load combinations as per IRC, including:

- Dead Load + Live Load

- Dead Load + Surcharge Load + Live Load

- Water Pressure + Dead Load + Live Load

Example Design Considerations:

- For a 2-lane box culvert, with Class AA loading:

- Top Slab: Designed to resist bending moments due to dead load, live load, and surcharge.

- Walls: Designed for both axial and flexural stress due to earth pressure and surcharge.

- Bottom Slab: Resists uplift pressure and bending due to subgrade reaction.

References

- IRC 6-2017: General Specifications for Loads and Stresses

- IRC 21: For the concrete mix and structural detailing requirements.

- IS 456: For concrete design and reinforcement detailing

JOURNAL PAPER GUIDELINES FOR ACSE

Submission Guidelines: ASCE encourages the submission of scholarly and practice-oriented articles to its journals. Before…

SHELTER WITH 25T CRANE DRAWING | PEB SHED |

Designing a shelter with a 25-ton capacity crane involves structural considerations to support the heavy…

kitchen marble design 30+

Here is a modern kitchen design with luxurious marble elements. It showcases a sleek and…

Plumbing Drawing

Creating a plumbing scheme drawing involves outlining the entire plumbing system of a building, showing…

Standard Road Details

Rigid & Flexible Road Details – Drawings & Requirements Road construction is broadly classified into…

Design of Gantry Girder

Designing a crane girder, which is a key structural component used in overhead cranes, involves…